iHF Standard Spur Gear Rack S45C Precision Linear Rack for Printing Machinery

Productfeatures:

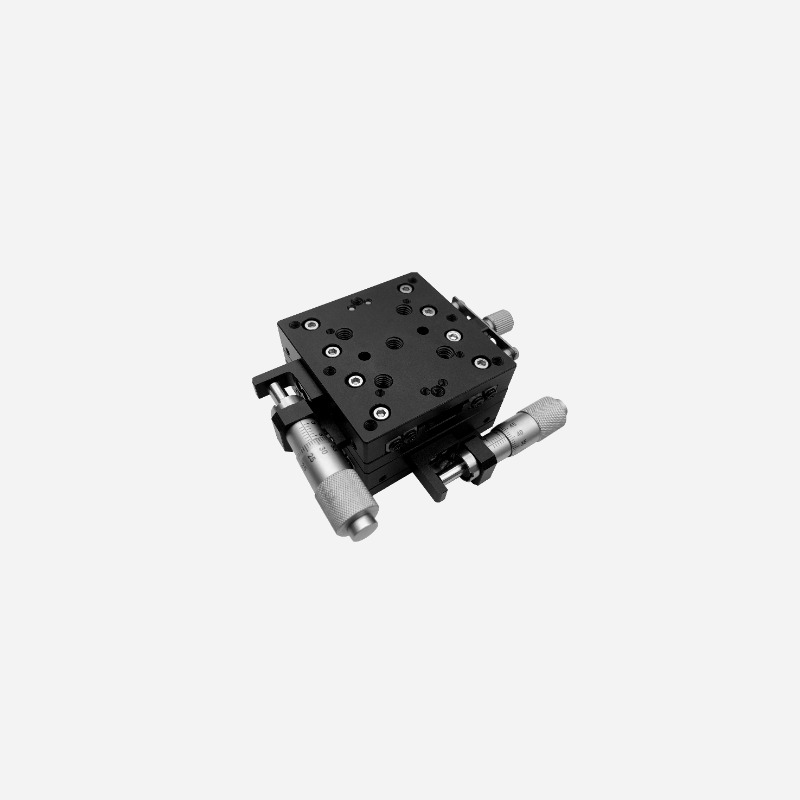

The standard spur rack features a 20°pressure angle and is precision-manufactured to deliver reliable linear motion in demanding applications. It is available in two material options: S45C medium carbon steel for superior strength and durability under high loads, and SUS304 stainless steel for excellent corrosion resistance in humid or chemically exposed environments.

Typical Applications:

Ideal for converting rotary motion to precise linear movement in:

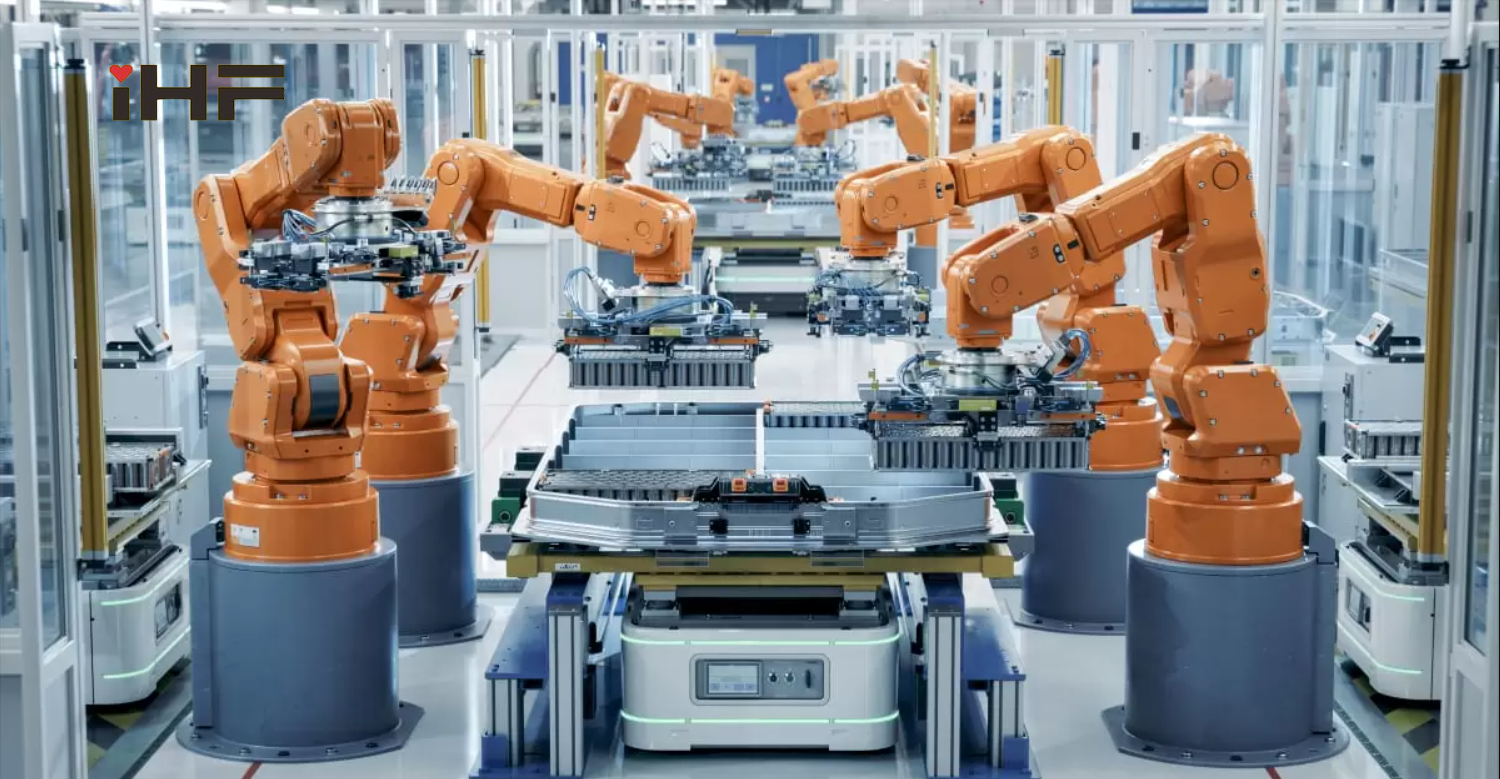

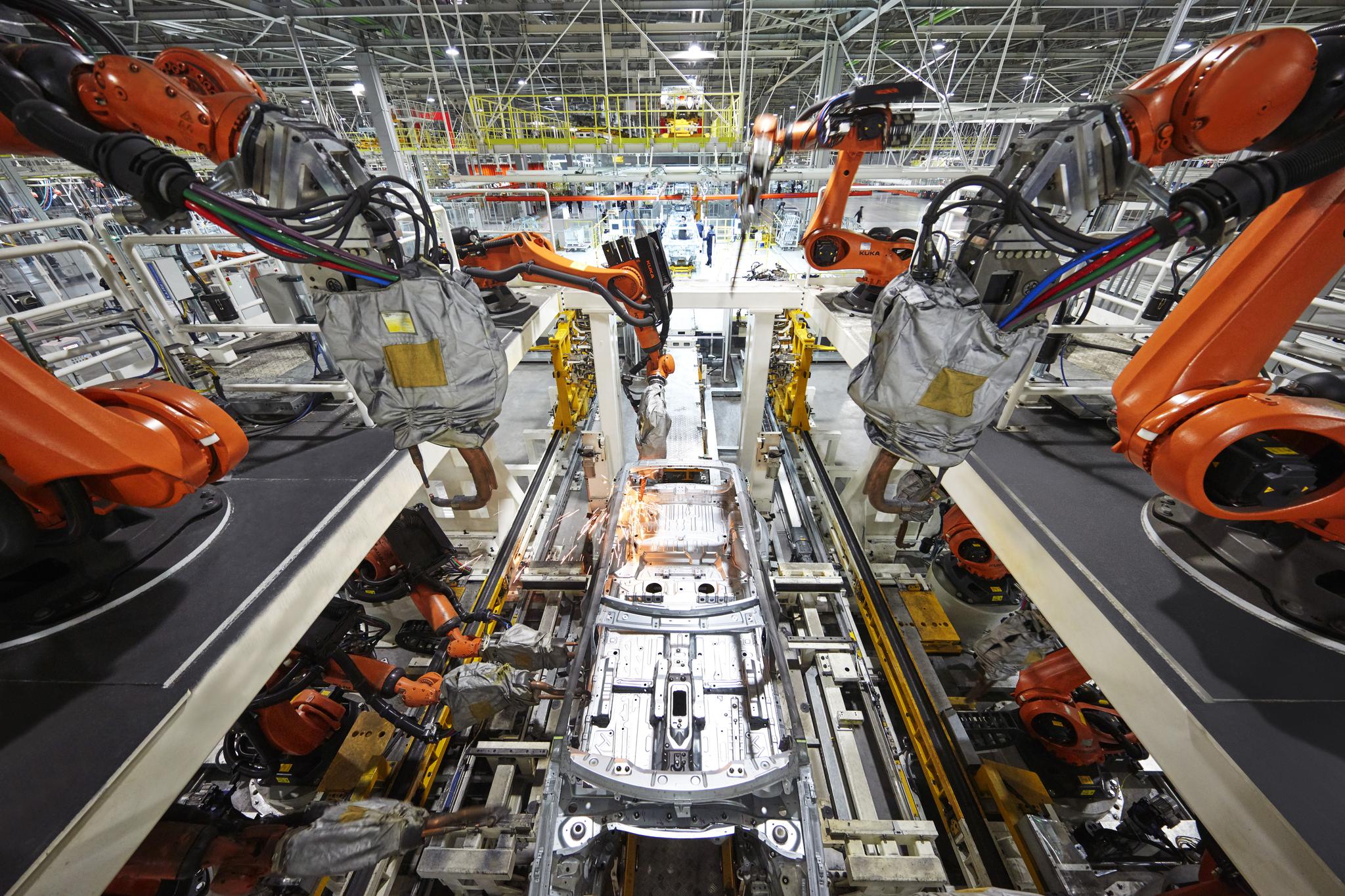

· Industrial Automation: CNC machine tool axes, linear actuators, pick-and-place systems, and automated assembly lines.

· Woodworking & Machining: CNC routers, engraving machines, cutting equipment, and material feed systems.

· Packaging & Material Handling: Conveyor positioning gates, lifting mechanisms, and cartesian robot systems.

· Precision Instrumentation: Optical positioning stages, medical device mechanisms, and testing equipment.

This rack series offers a robust solution for applications requiring high rigidity, accurate linear guidance, and long-term operational stability.

| Product Name | Spur Rack Pressure Angle 20° |

| Material | S45C/SUS304 |

| Product Model | CD01AF/CD01AA/CD01AU |

| Tooth Profile | Spur Gear |

| Transport Package | Cartons |

| Trademark | iHF |

| HS Code | 8483900090 |

| Manufacturing Process | Casting |

| Surface Treatment | Blackening |

| Surface Color | Black |

| Application | Industrial Automation and Robotics/Woodworking and Stone Processing/Construction Machinery and Logistics Equipment |

| Specification | Standard |

| Origin | Dongguan(Mainland) |

| Production Capacity | 500000 PCS/Year |

| Product | Standard Spur Rack |

| Customized | OEM, Drawings or Samples Customized |

| Tooth Profile | Spur Gear |

| Module | 1.0/1.5/2.0/2.5/3.0 |

| Length | 20~480 |

| Hole Machining | Bottom Threaded Hole(B)/Side Threaded Hole(S)/Side Counter-bore Hole(H)/No Hole(N) |

| Heat Treatment | HRC42~46 |

| Surface Treatment | Blackening |

| Material | S45C/SUS304 |

| Standard | DIN, ISO/GB, AGMA, JIS |

| Teeth Accuracy | DIN, ISO/GB Class 4, AGMA Class 13, JIS Class 0 |

| Weight | Max 15 Tons |

| Testing Equipment | Projecting apparatus, salt spray test, durometer, and coating thickness tester, 2D projector |

| Producing Equipment | CNC machine, automatic lathe macine, stamping machine, CNC milling machine,rolling maching, lasering, tag grinding machine etc. |

| Machining Process | Gear Hobbing, Gear Milling, Gear shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Application Industry | Robot industry, Medical industry, Making machine industry, Automation industry, 3C industry equipment, Packaging industry, UAV industry, New energy industry |

-

*

-

*

-

*

-

-

EN

EN Request Quote

Request Quote