Send Inquiry Now

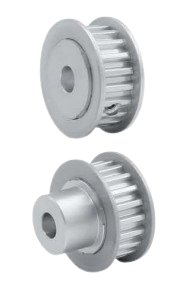

iHF Timing belt Pulley High Torque S2M HTD3M P2M

Productfeatures:

High Torque Capacity – The optimized tooth profile increases contact area and meshing force, allowing the pulley to handle higher torque output without deformation. Enhanced material strength and tooth rigidity make it suitable for heavy-load transmissions, frequent starts/stops, and high-impact environments.

Optimized Tooth Structure – Features like tooth root fillet transitions reduce stress concentration, improving fatigue life. Helical or specially designed teeth minimize noise and enhance meshing smoothness.

HTD Curved Tooth Timing Pulleys – Available in 2mm, 3mm, 5mm, and 8mm pitches, these pulleys deliver high-torque performance for medium-low speed heavy-duty drives.

SM Serrated Curve series – High-torque and high-speed compatibility.

PM Curved Tooth series – Superior cornering adaptability and ultra-quiet operation, ideal for high-speed precision conveying.

| Model. No. | Synchronous pulley for high torque |

| Material | 6061/S45C |

| Module | S2M/S3M/S5M/S8M HTD3M/HTD5M/HTD8M P2M/P3M/P5M/P8M |

| Shape | A/B/D/E/F/K |

| Transport Package | Each item should be packed in a polyethylene bag or wax paper and placed in one or more boxes. |

| Trademark | iHF |

| HS Code | 8448399000 |

| Manufacturing Process | Casting |

| Surface Treatment | Electroplating |

| Surface Color | Clear/Black/Silver |

| Application | Medical industry/Robot industry/Automation industry |

| Specification | Standard |

| Origin | Dongguan(Mainland) |

| Production Capacity | 550000 PCS/Year |

| Product | Standard timing pulley S2M/HTD3M/P2M |

| Customized | OEM, drawings or samples customized |

| Basic Shape | Type A/B/D/E/F/K |

| Surface Treatment | Clear anodizing, Black anodizing, Hard anodizing, Nickel plating, Black oxide |

| Material | 6061(aluminum);S45C(45# steel);SUS304(stainless steel) |

| Bore | Through hole, Tapped hole, Counterbore, Keyway |

| Tolerance Control | Outer diameter ±0.005mm Length diameter ±0.005mm |

| Standard | DIN, ISO/GB, AGMA, JIS |

| Teeth Accuracy | DIN, ISO/GB Class 4, AGMA Class 13, JIS Class 0 |

| Weight | Max 15 Tons |

| Testing Equipment | Projecting apparatus, salt spray test, durometer, and coating thickness tester, 2D projector |

| Producing Equipment | CNC machine, automatic lathe machine, stamping machine, CNC milling machine, rolling machine, lasering, tag grinding machine etc. |

| Machining Process | Gear hobbing, Gear milling, Gear shaping, Gear broaching, Gear shaving, Gear grinding and Gear lapping |

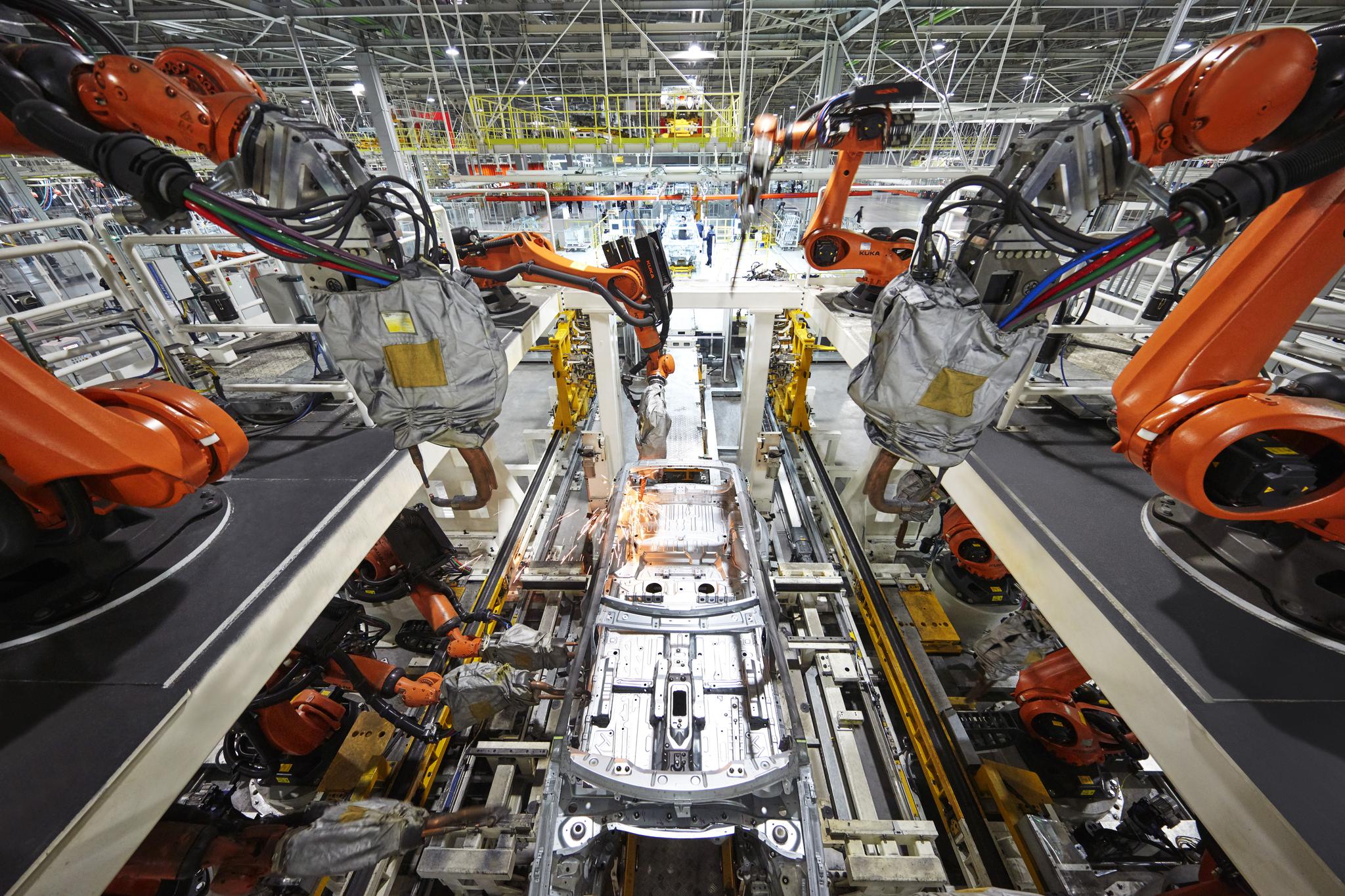

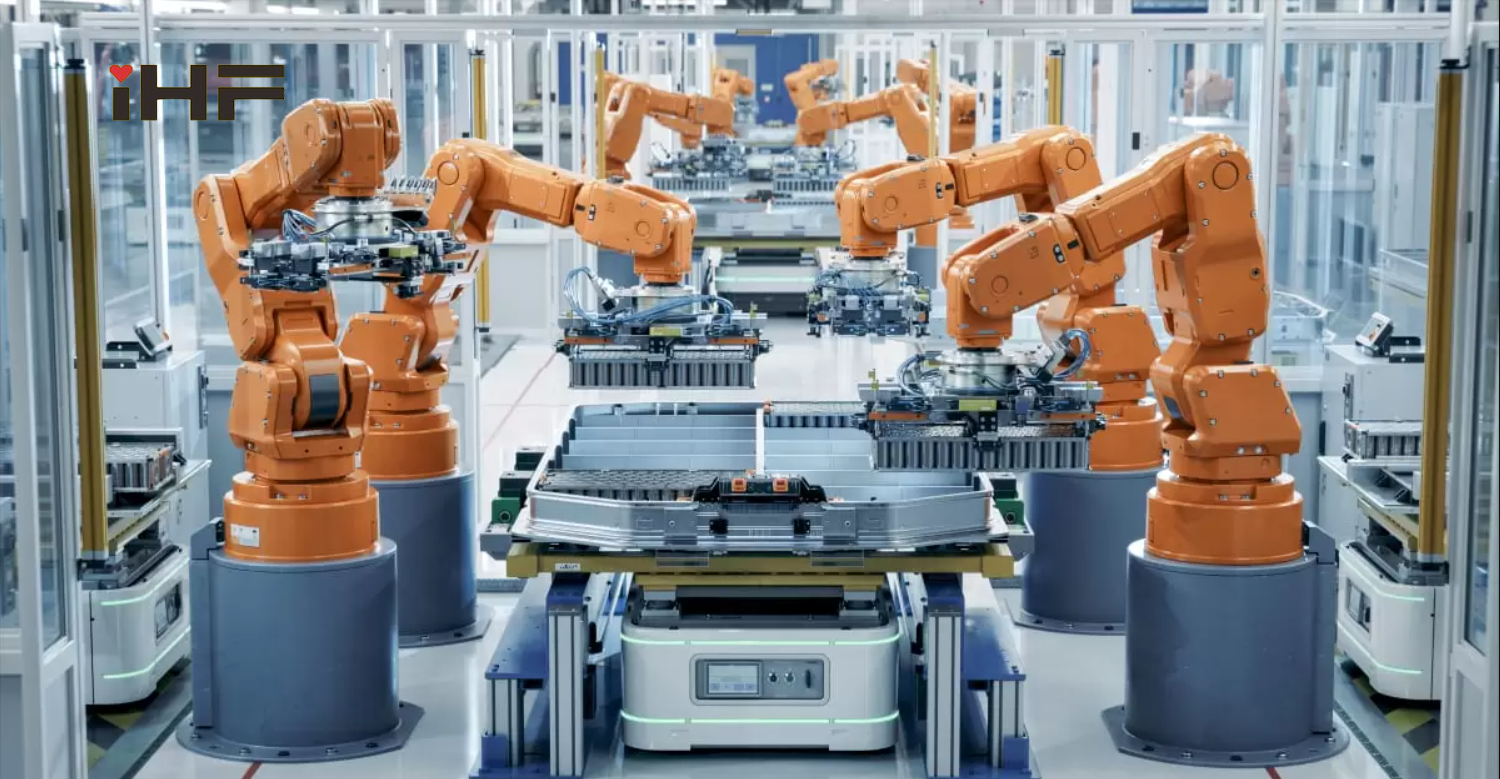

| Application Industry | Robot industry, Medical industry, Manufacturing machine industry, Automation industry, 3C industry equipment, Packaging industry, UAV industry, New energy industry |

-

*

-

*

-

*

-

-

EN

EN Request Quote

Request Quote