Find out more about our news >

Beyond Standard Chains: The Power of Custom Cable Carrier Solutions

In modern industrial automation, motion is no longer a simple linear requirement—it is a complex interaction between speed, precision, durability, and reliability. As machines become faster and more compact, the management of dynamic cables, hoses, and pneumatic lines has become a critical engineering challenge. This is where Custom Cable Carrier solutions play a decisive role.

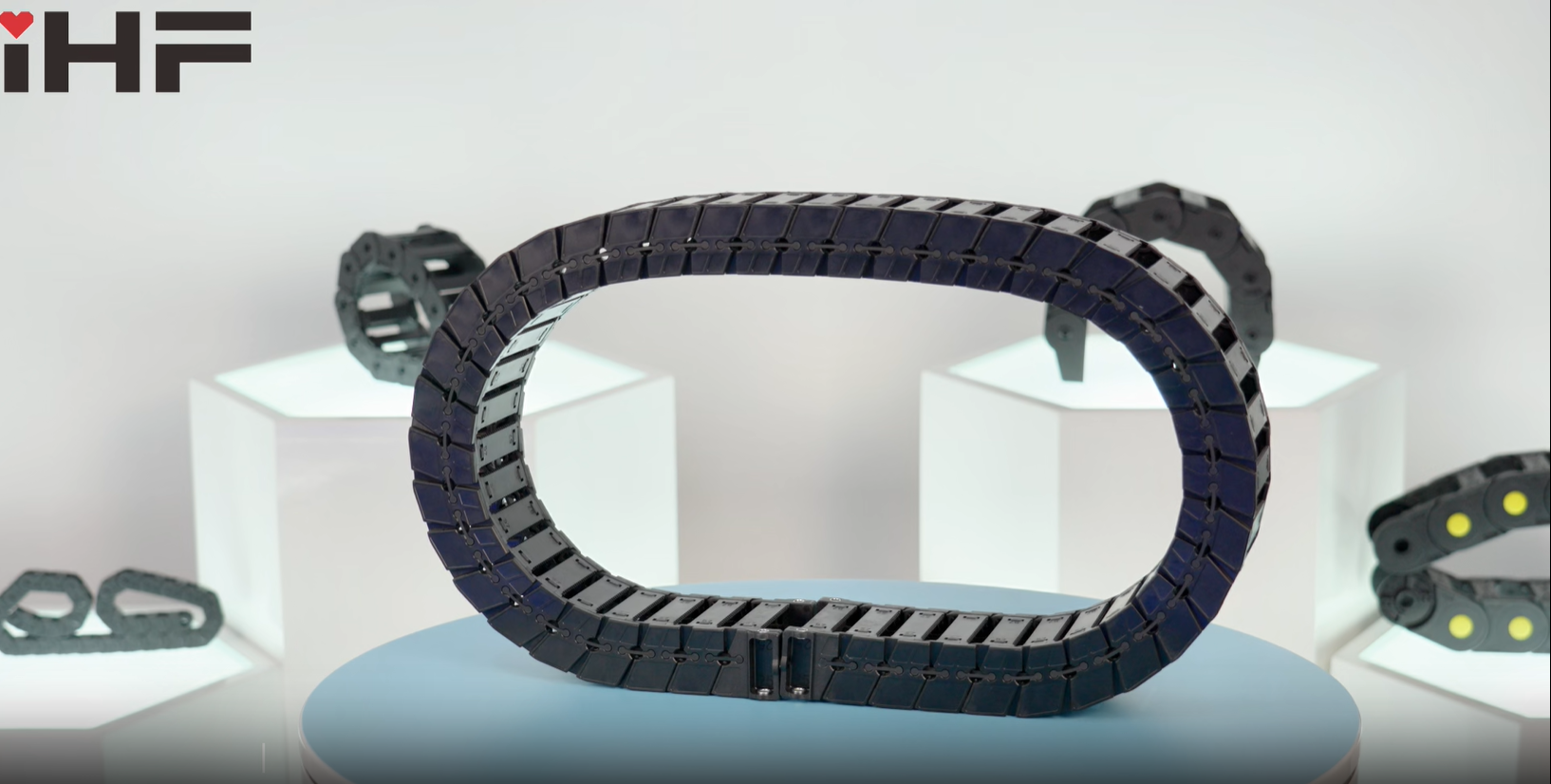

Understanding the Function of a Custom Cable Carrier

A cable carrier—also known as a drag chain or energy chain—is a mechanical guiding system designed to protect and organize cables and hoses in moving equipment. While standard models serve basic applications, complex machinery often requires custom cable carrier designs tailored to specific operating conditions.

A custom cable carrier is engineered according to:

Travel length and movement type

Cable diameter, quantity, and bending radius

Speed, acceleration, and load requirements

Environmental factors such as dust, heat, oil, or moisture

This level of customization ensures stable motion, minimizes cable wear, and reduces unplanned downtime.

Why Standard Cable Carriers Are Often Not Enough

As automation systems evolve, off-the-shelf cable carriers frequently fall short in real-world applications. Common limitations include:

Inadequate bending radius for sensitive cables

Insufficient load-bearing capacity

Poor resistance to harsh industrial environments

Limited compatibility with non-standard machine layouts

A Custom Cable Carrier addresses these issues by aligning mechanical design precisely with application requirements, rather than forcing the application to adapt to the component.

Key Engineering Advantages of Custom Cable Carrier Solutions

Optimized Cable Protection

Custom designs allow precise control of internal separation, ensuring that power cables, data cables, and fluid hoses are properly isolated. This reduces electromagnetic interference, abrasion, and premature failure.

Extended Service Life

By matching bending radius and chain geometry to actual motion parameters, custom cable carriers significantly extend cable and hose lifespan, lowering replacement frequency and maintenance costs.

Improved Machine Reliability

Stable and predictable cable movement reduces the risk of sudden cable breakage, which is often a root cause of unplanned equipment shutdowns.

Material Selection: Matching Performance with Environment

Professional Custom Cable Carrier manufacturers offer multiple material options, including:

High-strength reinforced plastic for lightweight, high-speed applications

Steel or stainless steel for heavy-duty loads and extreme environments

Hybrid designs combining strength and flexibility

Material choice directly impacts noise levels, wear resistance, chemical compatibility, and long-term performance. iHF Group provides technical consultation to ensure material selection aligns with operational demands.

Customization Dimensions That Matter

A truly effective Custom Cable Carrier is not defined by appearance but by engineering detail. Key customization parameters include:

Chain height and width matched to cable bundle size

Customized link pitch for smooth motion

Specialized end connectors for machine interfaces

Optional internal separators and strain relief systems

These details ensure seamless integration into both new equipment designs and retrofit projects.

Industry Applications for Custom Cable Carriers

Custom cable carrier systems are widely used across industries where dynamic motion is critical:

CNC machine tools and machining centers

Robotics and automation lines

Packaging and material handling systems

Laser cutting and plasma equipment

Semiconductor and electronics manufacturing

In each of these sectors, cable management reliability directly affects productivity and precision.

Why iHF Group Is a Trusted Custom Cable Carrier Partner

With deep experience in industrial motion solutions, iHF Group specializes in the design and manufacturing of Custom Cable Carrier systems tailored to demanding automation environments.

Core Capabilities of iHF Group

Engineering-driven customization based on real application data

Consistent manufacturing quality and dimensional accuracy

Support for OEM, system integrator, and distributor requirements

Scalable production for both standard and highly customized solutions

By focusing on functionality rather than generic specifications, iHF Group helps customers achieve higher equipment uptime and lower lifecycle costs.

Conclusion: Custom Cable Carriers as a Strategic Engineering Choice

In advanced automation systems, cable management is not a secondary concern—it is a foundational element of machine reliability. Custom Cable Carrier solutions enable engineers to optimize motion control, protect critical cables, and enhance system durability.

By partnering with experienced manufacturers such as iHF Group, companies can move beyond generic components and implement cable carrier systems engineered specifically for performance, longevity, and operational efficiency.

EN

EN Request Quote

Request Quote