Find out more about our news >

Precision Without Compromise: How Advanced Metal Couplings Power High-Performance Motion Control

In modern industrial automation and servo-driven systems, power transmission is no longer just about transferring torque from point A to point B. It is about accuracy, responsiveness, durability, and control. At the center of this demand lies a critical mechanical component: metal couplings.

1. Understanding Metal Couplings in Modern Drive Systems

Metal couplings are mechanical devices used to connect two rotating shafts, enabling torque transmission while compensating for misalignment. In high-precision environments, such as CNC machinery, robotics, semiconductor equipment, and servo-driven automation, the coupling must transmit motion without delay, distortion, or energy loss.

Compared to conventional couplings, high-performance metal couplings offer:

Zero or near-zero backlash

High torsional stiffness

Predictable dynamic behavior

Extended operational life

These characteristics make them indispensable in precision motion control.

2. High-Strength Stainless Steel Diaphragm Structure

2.1 Robust Torsional Rigidity and Torque Capacity

At the core of advanced metal couplings is a high-strength stainless steel diaphragm structure. This design provides exceptional torsional rigidity, allowing the coupling to transmit torque with minimal angular deflection—even under dynamic load conditions.

Key performance benefits include:

High torque capacity relative to size

Immediate torque response

Zero power loss during transmission

For servo applications where acceleration and deceleration occur rapidly, this structural rigidity ensures that commanded motion translates directly into mechanical output.

2.2 Immediate Response for Servo Systems

In closed-loop servo systems, response time is critical. Stainless steel diaphragm metal couplings eliminate the elastic lag commonly found in rubber or polymer couplings. As a result, they deliver instantaneous motion response, improving positioning accuracy and system stability.

3. Zero-Backlash Design for Precision Motion Transfer

3.1 Synchronous Bidirectional Torque Transmission

One of the defining advantages of premium metal couplings is their zero-backlash design. This ensures that torque transmission is fully synchronous, with identical characteristics in both forward and reverse rotation.

This is particularly important in applications involving:

Frequent direction changes

Interpolated motion paths

High-resolution feedback systems

Zero backlash eliminates positional errors, improves repeatability, and enhances overall system precision.

3.2 Consistency in Dynamic Applications

In dynamic servo environments, any backlash can lead to vibration, control instability, or accelerated wear. Metal couplings designed with diaphragm technology maintain consistent torque transmission even during rapid load reversals, ensuring predictable system behavior.

4. Multi-Ply Stainless Steel Diaphragms and Misalignment Compensation

4.1 Elastic Compensation Without Sacrificing Accuracy

While rigidity is essential, real-world systems inevitably experience misalignment. Advanced metal couplings address this through multi-ply stainless steel diaphragms, which provide elastic compensation for:

Radial misalignment

Angular misalignment

Axial displacement

This flexibility is achieved without introducing backlash or reducing torsional stiffness.

4.2 Optimized Stress Distribution and Extended Service Life

The multi-layer diaphragm design distributes operational stress evenly across the material, reducing fatigue concentration. This significantly extends service life, even in high-speed or high-cycle applications.

For specialized operational profiles requiring reduced mass and inertia, a single-diaphragm configuration can be used. This low-mass design enhances system responsiveness while maintaining core performance characteristics.

5. Maintenance-Free Operation in Harsh Industrial Environments

5.1 Resistance to Oils, Corrosion, and Contaminants

Industrial environments often expose components to oils, coolants, chemicals, and airborne contaminants. Stainless steel metal couplings are inherently resistant to corrosion and chemical attack, making them ideal for demanding conditions.

Unlike lubricated couplings, diaphragm-based metal couplings operate without lubrication, eliminating maintenance requirements and reducing downtime.

5.2 Reliability Without Intervention

The maintenance-free design ensures stable performance over long service intervals. For automated production lines and unmanned systems, this reliability translates directly into higher uptime and lower total cost of ownership.

6. Hybrid Diaphragm Design: Balancing Torque and Inertia

A key innovation in advanced metal couplings is the integration of circular and rectangular stainless steel elastic diaphragms. This hybrid configuration balances two traditionally conflicting requirements:

High torque transmission capacity

Ultra-low rotational inertia

By optimizing diaphragm geometry, this design delivers fast acceleration, precise deceleration, and excellent dynamic response—ideal for critical motion control applications in servo systems and industrial automation.

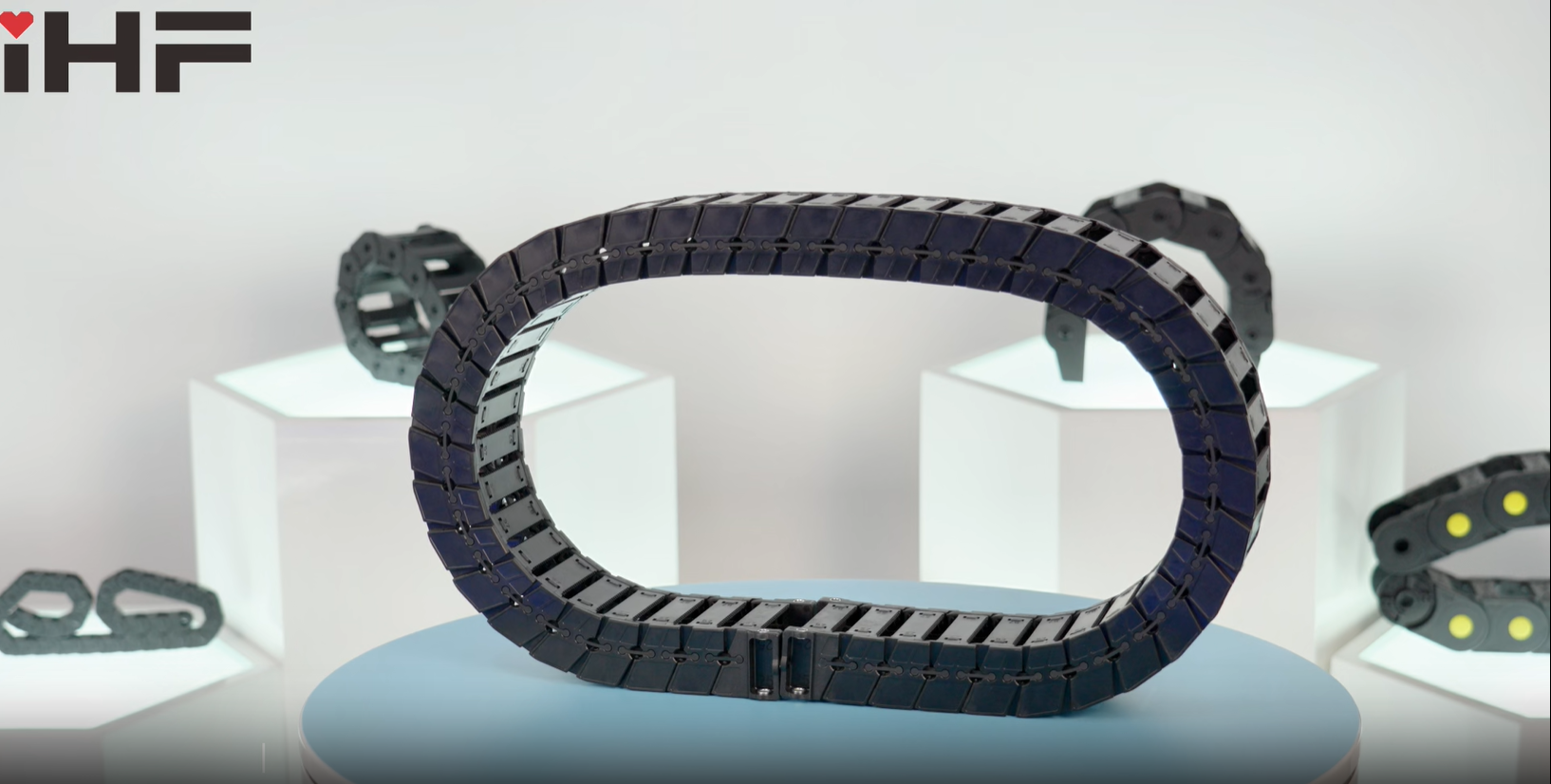

7. Applications Across Precision Industries

Metal couplings with diaphragm structures are widely used in:

Servo motor and encoder connections

CNC machine tools

Robotics and automation equipment

Semiconductor and electronics manufacturing

Medical and inspection systems

iHF Group designs metal couplings with these applications in mind, ensuring compatibility with high-speed, high-precision drive architectures.

8. Why Engineering Expertise Matters

Not all metal couplings perform equally. True performance depends on:

Material selection and heat treatment

Diaphragm geometry and ply configuration

Precision machining and balance control

With a strong focus on engineering accuracy and application-specific design, iHF Group delivers metal coupling solutions that meet the stringent demands of modern motion control systems.

Conclusion: Metal Couplings as Precision Enablers

Metal couplings are not merely mechanical connectors—they are precision enablers within advanced drive systems. By combining high-strength stainless steel diaphragms, zero-backlash transmission, misalignment compensation, and maintenance-free durability, modern metal couplings support higher accuracy, faster response, and long-term reliability.

For industries that demand uncompromising motion control performance, metal couplings engineered by iHF Group represent a strategic investment in system precision and operational stability.

EN

EN Request Quote

Request Quote