Find out more about our news >

Efficiency at 90 Degrees: The Spiral Bevel Advantage in iHF Group Gearboxes

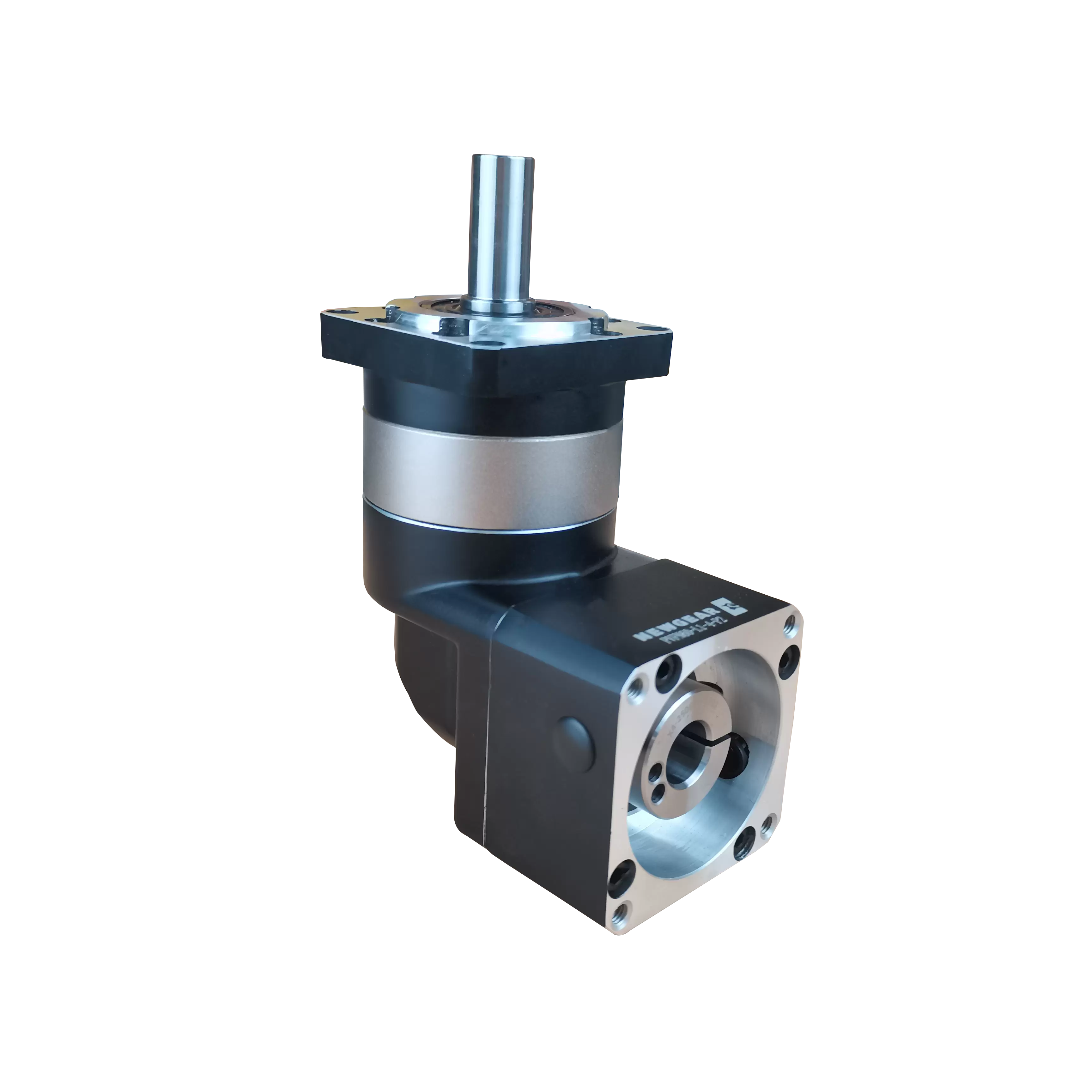

In modern mechanical systems, efficiency, stability, and motion accuracy determine the success of automation, industrial equipment, and power transmission applications. Among these critical components, the Spur Right Angle Bevel Gearbox has become an essential solution for enabling compact layouts and right-angle power redirection without sacrificing torque capacity or transmission precision.

As industries move toward smarter and more optimized mechanical designs, iHF Group continues to deliver reliable, high-performance gearbox solutions engineered to meet demanding application requirements.

1. Spiral Bevel Gear Mechanism for Reliable Right-Angle Power Transfer

At the core of the Spur Right Angle Bevel Gearbox is a spiral bevel gear mechanism, designed specifically to achieve smooth, efficient, and stable right-angle steering output. Compared with traditional straight bevel gears, spiral bevel gears offer:

Reduced noise and vibration

Higher torque transmission capability

Better load distribution

Improved shock-load resistance

This makes the gearbox particularly suitable for automated equipment, conveyor systems, machining tools, and industrial machinery that require both compactness and long service life.

By integrating advanced gear geometry and precision machining, iHF Group ensures that each gearbox delivers robust right-angle motion control even under continuous or high-load operation.

2. Square Flange Shaft Output for Flexible Integration

To simplify integration and maximize compatibility across machinery platforms, the Spur Right Angle Bevel Gearbox features a square flange shaft output. This structure offers several advantages:

Simple and stable mounting

Higher stiffness in cantilevered load conditions

Compatibility with a wide range of standardized mechanical interfaces

The square flange design enhances long-term accuracy and structural rigidity, making it ideal for applications requiring a stable and predictable transmission interface, such as packaging machinery, printing equipment, and automated manufacturing units.

3. Cost-Effective Design Combining Bevel and Spur Gear Transmission

One of the standout characteristics of this gearbox is its hybrid transmission architecture, pairing a spiral bevel gear mechanism with a spur gear stage. This combination supports:

Optimized cost-effectiveness

Excellent transmission efficiency

Reduced maintenance requirements

Compact single-cantilever structure for space-critical layouts

The single-cantilever design achieves an impressive balance between size, cost, and performance, giving manufacturers a highly economical solution without compromising on reliability.

For OEMs requiring scalable, budget-sensitive transmission configurations, the gearbox provides a superior value-performance ratio.

4. Input Shaft Available with Keyway for Secure Power Transfer

To enhance mechanical adaptability, the input shaft of the Spur Right Angle Bevel Gearbox can be configured with a precision-machined keyway. This ensures:

Strong, slip-free torque coupling

Faster integration into existing drive systems

Greater compatibility with motors, actuators, and linear equipment

The keyway design also strengthens the mechanical connection under high-frequency start-stop cycles, contributing to improved long-term operational stability.

5. Controlled Backlash of 8–16 arcmin for Applications Requiring Precision

Backlash directly affects motion accuracy, especially in automation, positioning systems, and synchronized motion applications. The gearbox maintains a controlled return clearance of 8–16 arcmin, striking an optimal balance between precision and affordability.

This level of backlash is suitable for:

Automated production lines

Robotics and articulated mechanisms

Conveyor synchronization

Metering systems

Packaging and filling equipment

Through strict machining tolerances and quality control, iHF Group ensures each gearbox maintains consistent precision over extended service cycles.

6. Why iHF Group Leads in Precision Gearbox Manufacturing

As a company specializing in transmission solutions, iHF Group combines advanced engineering, strict manufacturing standards, and deep industry experience. Their gearboxes are known for:

High mechanical reliability

Excellent price-performance ratio

Strong customization capabilities

Industry-specific design optimization

Quality control aligned with international standards

By continuously improving its gear geometry, material selection, heat treatment, and assembly processes, iHF Group delivers products that meet the evolving needs of global manufacturing.

7. Applications Across Diverse Industrial Sectors

The Spur Right Angle Bevel Gearbox is widely adopted in:

Automation and motion control

CNC and machining equipment

Food and packaging lines

Material handling conveyors

Printing and labeling machines

Industrial robotics

Light and mid-load power transmission

Its compactness, durability, and cost advantage make it a preferred choice for OEM manufacturers seeking reliable right-angle transmission solutions.

Conclusion

The Spur Right Angle Bevel Gearbox from iHF Group represents a powerful combination of engineering precision, stable right-angle power transfer, and cost-efficient structural design. With spiral bevel gear mechanisms, square flange output, flexible keyway options, and controlled backlash, it meets the performance expectations of modern industrial systems.

For industries needing a compact, robust, and economical right-angle transmission solution, iHF Group provides a gearbox designed for long-term efficiency and reliability.

EN

EN Request Quote

Request Quote