Find out more about our news >

Enhancing Automation Efficiency with Advanced Cable Carriers

Automation has revolutionized modern manufacturing, logistics, and industrial processes. Central to maintaining reliable motion and uninterrupted operation is the proper management of cables and hoses. This is where cable carriers for automation become essential.

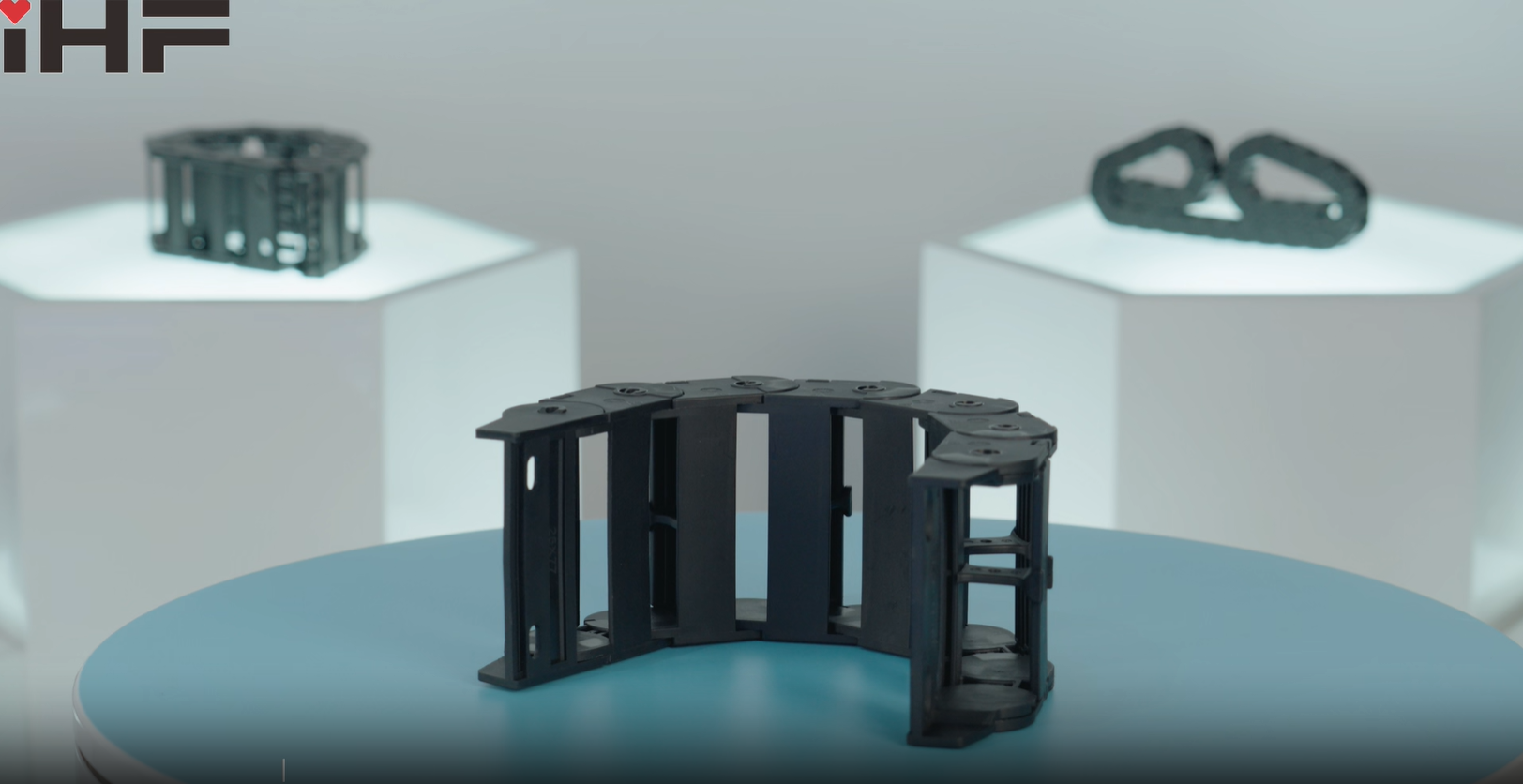

Cable carriers guide, protect, and support energy, data, and fluid lines, preventing tangling, wear, and mechanical stress. Companies like iHF Group design advanced cable carriers that combine durability, flexibility, and precision engineering for high-performance industrial environments.

Core Functions of Cable Carriers

Protection and Safety

Cable carriers protect cables and hoses from abrasion, sharp bends, and environmental contaminants. By reducing physical stress, they extend the lifespan of critical electrical and hydraulic lines.

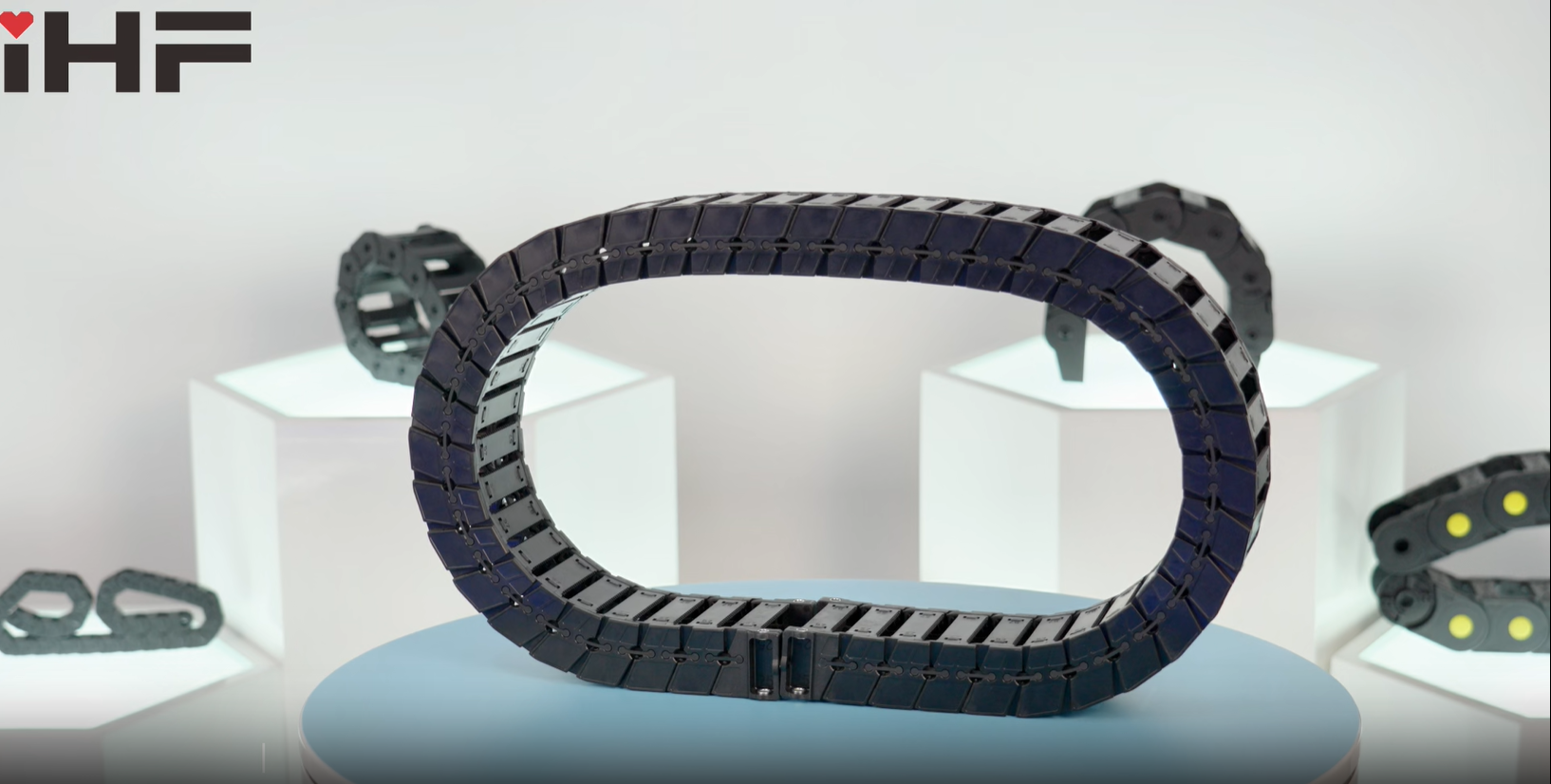

Movement and Flexibility

Modern automated systems require high-speed, multi-axis motion. Cable carriers allow smooth travel of cables and hoses along complex paths, maintaining consistent bend radii and preventing signal degradation.

Organization and Maintenance

Well-designed carriers organize multiple cables into a single, manageable unit, simplifying installation, inspection, and replacement.

Types of Cable Carriers

Open vs. Enclosed Designs

Open carriers: Offer easy access for cable installation and inspection, ideal for low-dust environments.

Enclosed carriers: Provide full protection against dust, liquids, and debris, suitable for harsh industrial conditions.

Single-Axis and Multi-Axis Carriers

Single-axis carriers manage linear motion, while multi-axis designs accommodate complex robotic or gantry movements, supporting both horizontal and vertical travel.

Modular vs. Fixed-Length

Modular carriers: Flexible, adjustable, and easy to extend or reconfigure.

Fixed-length carriers: Economical and simple for repetitive motion applications.

iHF Group produces a wide range of carriers, optimized for specific motion profiles, load capacities, and environmental conditions.

Engineering Considerations

Bend Radius and Cable Life

Maintaining the proper bend radius is critical to prevent cable fatigue and failure. Cable carriers are engineered to accommodate the dynamic bending of multiple lines without exceeding manufacturer-recommended limits.

Load Capacity and Speed

Industrial automation often demands high-speed motion under variable load conditions. Properly designed carriers balance low friction, weight distribution, and structural integrity to maintain consistent performance.

Material Selection

Cable carriers can be made from:

Plastic composites: Lightweight, corrosion-resistant, and suitable for medium-duty applications.

Steel or aluminum: High-strength, durable, ideal for heavy loads or extreme environments.

iHF Group customizes carrier materials and configurations to align with both operational and environmental requirements.

Application Areas

Robotics and Material Handling

Cable carriers enable robotic arms and automated material handling systems to operate continuously without cable wear or entanglement.

CNC Machines and Precision Manufacturing

High-speed machining and laser systems rely on cable carriers to maintain signal integrity, energy delivery, and coolant routing.

Warehouse Automation and Conveyors

Cable carriers streamline power and data management across automated storage and retrieval systems, enhancing efficiency and reliability.

Installation and Maintenance Best Practices

Proper alignment: Ensures minimal stress on cables and hoses.

Secure mounting: Prevents vibrations and mechanical fatigue.

Periodic inspection: Detects wear, debris accumulation, or misalignment early.

Cable separation: Organizing high-voltage, signal, and fluid lines reduces interference and mechanical stress.

With these measures, carriers from iHF Group deliver long-term operational reliability and reduce unplanned downtime.

Benefits of Using Advanced Cable Carriers

Extended cable and hose life

Reduced maintenance costs

Enhanced system reliability

Improved safety for operators

Optimized motion efficiency

By integrating advanced cable carriers into automated systems, manufacturers achieve smoother operation, higher uptime, and improved ROI.

Conclusion: Cable Carriers as the Backbone of Reliable Automation

Cable carriers are critical for ensuring that modern automated systems operate safely, efficiently, and without interruption. With proper design, installation, and maintenance, cable carriers for automation protect investments, extend equipment life, and enable higher productivity.

iHF Group provides engineered solutions that combine flexibility, durability, and precision, supporting the evolving needs of industrial automation across sectors.

EN

EN Request Quote

Request Quote