Send Inquiry Now

EN

EN

Request Quote

Request Quote

-

Name:

-

*Company Name:

-

*Email:

-

Motor Model:

-

Motor Power:

-

Gear Ratio:

-

Precision Requirement:

-

Motor Drawing:

-

Select Model Now:

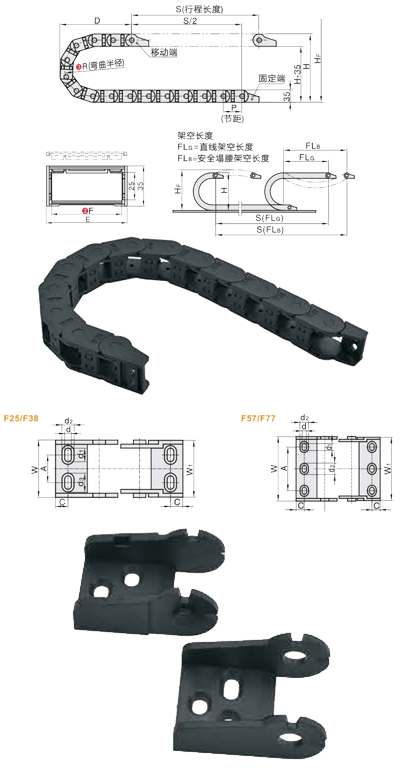

iHF Cable Carrier Chain Plastic Drag Chain for Wires Protection

Product features:

Drag Chain Installation Method

1. Open the Cover Plate: Use a flat-head screwdriver to vertically insert into the opening holes at both ends of the cover plate and open it.

2. Place the Pipes/Cables: Lay the cables, hoses, etc., into the Cable Carrier channel.

3. Close the Cover Plate: Secure the cover plate back in place.

4. Secure the Cables: Both ends of the cables (fixed end and moving end) must be fixed using tension relief devices to eliminate stress.

Characteristics of Drag Chain Structure

1. Basic Composition: The shape resembles a tank track, consisting of multiple flexibly rotatable unit links connected in series.

2. Standardization and Selectivity: Within the same series, the inner height, outer height, and pitch are identical, while the inner height and bending radius (R) offer multiple options.

3. Convenient Design: Each unit link is composed of left and right chain plates along with upper and lower cover plates. Every cover plate can be opened, allowing pipelines and cables to be placed directly inside without threading.

4. Optional Dividers: Partition plates can be added to segment the internal space as needed, effectively preventing movement and torsional deformation of pipelines and cables.

Core Advantages of Drag Chains

1. Core Function: Specifically designed for reciprocating motion, effectively guiding and protecting internal cables, hydraulic hoses, pneumatic tubes, water pipes, etc.

2. Ease of Use: Each section is openable for easy installation and maintenance; operates with low noise, high wear resistance, and supports high-speed movement.

3. Wide Application: Extensively used in CNC machine tools, electronic equipment, injection molding machines, robotic arms, lifting & transportation, automated warehouses, and other fields.

4. Supply Assurance: Can serve as a 1:1 replacement for market-standard products, with professional engineer support for selection, centralized procurement to reduce costs, and ample stock availability.

Drag Chain

| Type | Bending radius R | Number of chain links N | Joint | H | D | K | Actual spatial height HF | OUTER WIDTH E | |

| Series code | Inner width F | ||||||||

| ZH07SJ | 25 | 55 | 1~ | ZHO8SS25 ZHO8ST25 | 145 | 125 | 276 | 175 | 39 |

| 75 | 185 | 150 | 346 | 215 | |||||

| 100 | 235 | 170 | 414 | 265 | |||||

| 125 | 285 | 195 | 496 | 315 | |||||

| 150 | 335 | 220 | 578 | 365 | |||||

| 175 | 385 | 245 | 660 | 415 | |||||

| 200 | 435 | 270 | 742 | 465 | |||||

ZH07SJ ZH07SK | 38 | 55 | ZHO8SS3 8ZHO8ST38 | 145 | 125 | 276 | 175 | 52 | |

| 75 | 185 | 150 | 346 | 215 | |||||

| 100 | 235 | 170 | 414 | 265 | |||||

| 125 | 285 | 195 | 496 | 315 | |||||

| 150 | 335 | 220 | 578 | 365 | |||||

| 175 | 385 | 245 | 660 | 415 | |||||

| 200 | 435 | 270 | 742 | 465 | |||||

| 57 | 55 | ZHO8SS5 7ZH08ST57 | 145 | 125 | 276 | 175 | 71 | ||

| 75 | 185 | 150 | 346 | 215 | |||||

| 100 | 235 | 170 | 414 | 265 | |||||

| 125 | 285 | 195 | 496 | 315 | |||||

| 150 | 335 | 220 | 578 | 365 | |||||

| 175 | 385 | 245 | 660 | 415 | |||||

| 200 | 435 | 270 | 742 | 465 | |||||

| 77 | 55 | ZH08SS7 7ZH08ST77 | 145 | 125 | 276 | 175 | 91 | ||

| 75 | 185 | 150 | 346 | 215 | |||||

| 100 | 235 | 170 | 414 | 265 | |||||

| 125 | 285 | 195 | 496 | 315 | |||||

| 150 | 335 | 220 | 578 | 365 | |||||

| 175 | 385 | 245 | 660 | 415 | |||||

| 200 | 435 | 270 | 742 | 465 | |||||

| Type | Pitch P | Maximum cable inspection diameter mm | Maximum overhead load-bearing capacity kg/m | Maximum overhead length m | Maximum allowable travel m | Maximum allowable vertical suspension m | Weight kg/m | ||

| Series code | Inner width F | ZH07SJ | ZHO7SK | ||||||

| ZH07SJ | 25 | 45.8 | 22 | 1.0 | 1.3 | 70 | 30 | ≈0.67 | - |

ZH07SJ ZH07SK | 38 | ≈0.78 | ≈0.8 | ||||||

| 57 | ≈0.86 | ≈0.88 | |||||||

| 77 | ≈0.96 | ≈1.0 | |||||||

Connector

| Type | A | W | W1 | W2 | C | d | d1 | d2 | d3 | |

| Series code | Inner width F | |||||||||

ZH08SS ZHO8ST | 25 | 16 | 39 | 39 | 39 | 11.8 | 6.5 | 6.5 | - | 13.7 |

| 38 | 23 | 52 | 52 | 52 | 12 | 6.2 | 10.4 | 11.2 | 15.5 | |

| 57 | 40 | 71 | 71 | 71 | ||||||

| 77 | 60 | 91 | 91 | 91 | ||||||

-

*

-

*

-

*

-

-