Find out more about our news >

HeFa Gear Honored as "Advanced Manufacturing Industry Pioneer," Continues Deepening Focus in Transmission Field

On December 15th, Mr. Cao, Chairman of the iHF Group, attended the 2023 Shenzhen Advanced Manufacturing "Red Sail Award" Ceremony, hosted by the Shenzhen Electronic Equipment & Intelligent Equipment Industry Association. HeFa Gear was awarded the "Advanced Manufacturing Industry Pioneer Award" in recognition of its sustained dedication and innovation within the precision transmission sector, marking another significant industry endorsement.

Since entering the gear manufacturing industry in 1998, the company has continuously adapted to market demands over its 24-year history, successfully transforming from a traditional manufacturer into a modern integrated service provider.

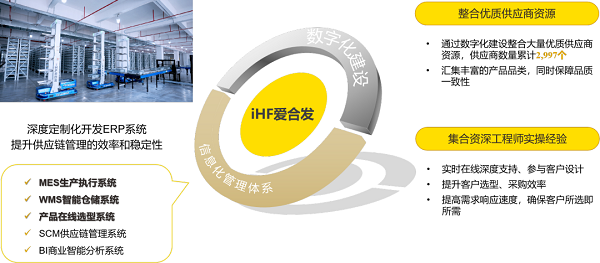

Digital Transformation Enhances Efficiency

Recognizing the critical importance of digitalization, HeFa Gear's management engaged in thorough discussions and on-site evaluations with the Huawei Cloud Longhua Innovation Center. This led to the implementation of the Huawei Cloud Digital Factory Solution.

The solution deployed 115 data acquisition devices based on Huawei Cloud IoT Edge services, enabling real-time monitoring of equipment operations and work order progress. This significantly improved the visualization of Overall Equipment Effectiveness (OEE) and management efficiency. Furthermore, the integration of the company's ERP (Enterprise Resource Planning) financial system with its MES (Manufacturing Execution System) broke down data silos, establishing integrated business-financial operations. This integration resulted in more accurate order cost accounting, real-time access to production data, and effectively drove capacity enhancement and cost optimization.

Strategic Transformation Expands Business Scope

The company's development path is clearly defined:

1998-2014: Focused on R&D and production of custom non-standard gears.

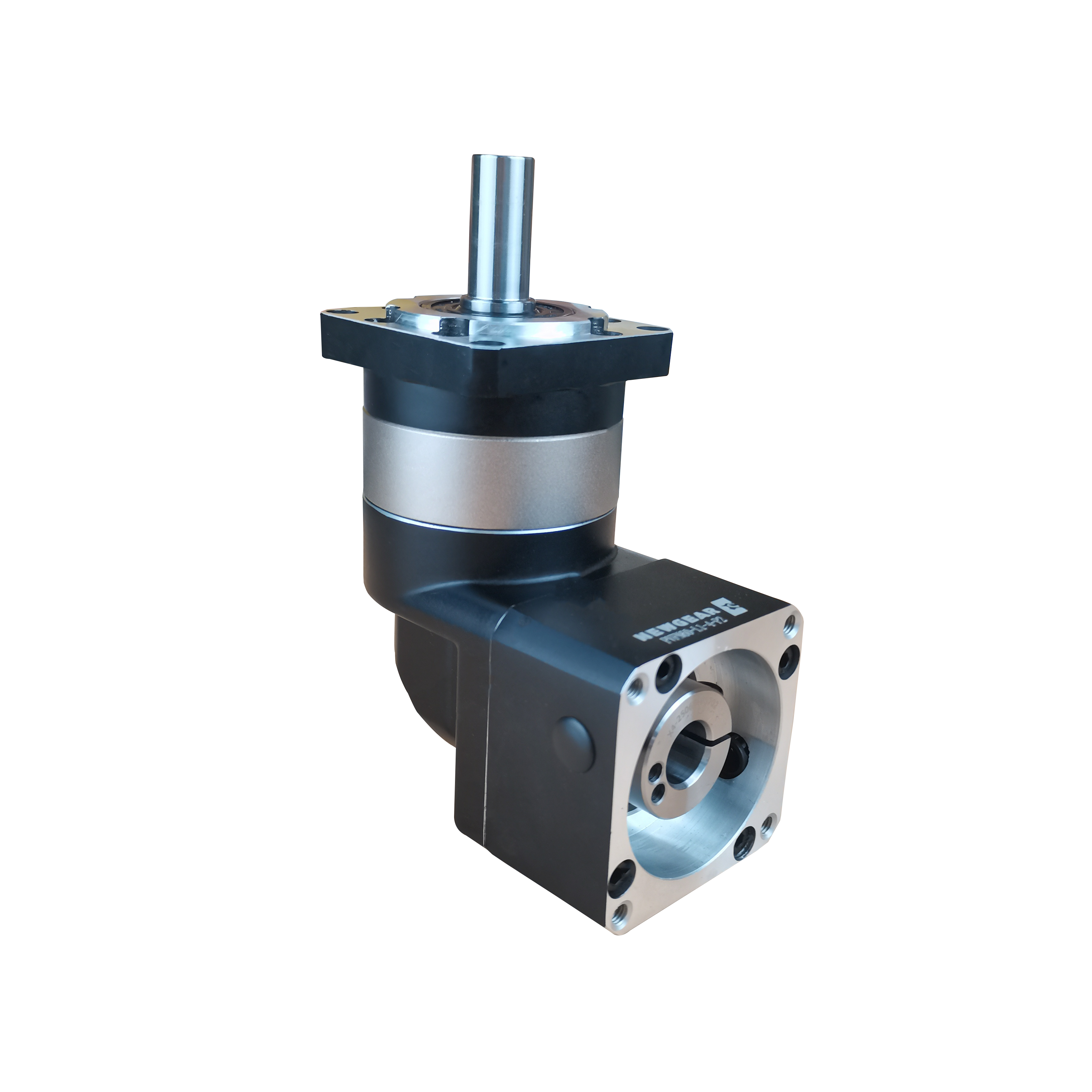

2014: Expanded into standard gears, timing pulleys, planetary gearboxes, and other structural components, overcoming capacity limitations of custom manufacturing.

2018: Established its wholly-owned subsidiary, iHF Industrial Transmission Technology (Guangdong) Co., Ltd., shifting the business model towards "Centralized Procurement + Services."

2020-Present: Launched the "iHF AiHeFa FA Automation Centralized Procurement Platform", integrating its "Self-Produced" and "Carefully Selected" series of industrial standard parts. This completed the transition into a one-stop automation component procurement and service platform, achieving shifts from "Specialized to Comprehensive," "Single to Integrated," and "Backup Supplier to Preferred Supplier" (with partners including leading companies like Foxconn, Honda, Mindray, and DJI).

Currently, HeFa Gear's products are widely applied across industries including medical devices, laser equipment, machine tools, robotic arms, and industrial robots.

Strengthening Foundations, Committed to Quality

HeFa Gear consistently adheres to the principle of "Meeting customer needs with quality and service" and is dedicated to advancing the precision transmission field. Through enhanced process management, robust quality foundations, and continuous innovation, the company relentlessly improves product quality and brand value, strengthening its core competitiveness.

This commitment has garnered significant authoritative recognition, including:

2019: National High-Tech Enterprise certification.

2020: Shenzhen Level-3 Work Safety Standardization Enterprise certification.

2021: Designation as a Shenzhen Specialized, Refined, Unique, and New (SRUN) SME.

2022: Approval as the Guangdong Provincial Engineering Technology Research Center for Mechanical Industrial Gear Transmission; Recognized as a Longhua District Intelligent Manufacturing and Modern Service Industry Benchmark Enterprise.

2023: Awarded National-Level "Little Giant" (SRUN Leading) Enterprise designation; Included in the Longhua District Enterprise New Apprenticeship Training Program.

Delivering a One-Stop Industrial Platform

To better serve automation and equipment manufacturing enterprises, HeFa Gear operates the iHF FA Automation Centralized Procurement Platform. The platform offers 129 product categories encompassing 480,000 SKUs, including timing pulleys, timing belts, planetary gearboxes, linear modules, ball screws, and linear guides. It provides both "Self-Produced" and "Carefully Selected" standard parts, aiming to deliver a one-stop procurement experience that saves customers time, effort, and cost.

The "Industry Pioneer Award" under the "Red Sail Award" banner affirms HeFa Gear's past efforts. Moving forward, the company will continue to deepen its expertise in the transmission field, enriching its portfolio of automation components and solutions, and remain committed to contributing to the advancement of China's manufacturing.

EN

EN Request Quote

Request Quote