Find out more about our news >

High-Torque and Low-Noise Motion Control with Custom Helical Gear Reducer

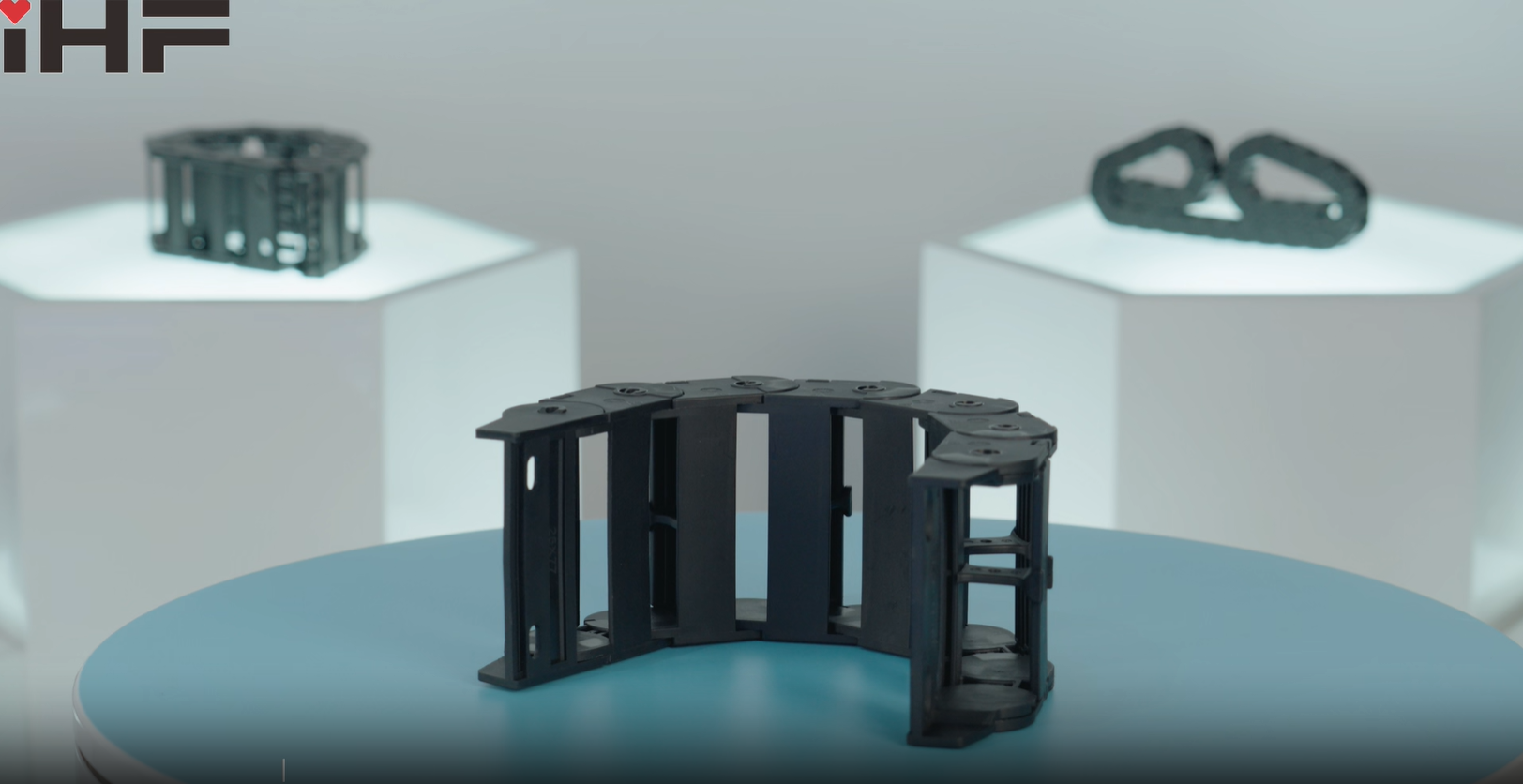

In modern industrial automation and power transmission systems, efficiency, reliability, and precision are critical to maintaining productivity. Among the many mechanical components that drive these operations, the iHF Group custom helical gear reducer has become a widely preferred solution. Known for its high torque capacity, low noise operation, and exceptional durability, this gear reducer provides the backbone for smooth motion control in demanding industrial environments.

What Is a Helical Gear Reducer

A helical gear reducer is a type of gearbox that uses helical gears, which feature angled teeth that engage gradually during operation. Unlike spur gears, which engage all at once, helical gears allow smoother and quieter operation with greater load-carrying capacity.

When customized, the gear reducer can be engineered to match specific torque, speed, and dimensional requirements of industrial applications. A custom helical gear reducer ensures optimized performance, long service life, and improved efficiency tailored to unique system demands.

Key Features of Custom Helical Gear Reducers

High Torque Transmission

Thanks to the angled gear teeth and robust gear design, helical reducers can handle higher torque loads compared to other gear types of similar size. This makes them ideal for heavy-duty applications.

Low Noise and Smooth Operation

The gradual meshing of helical gears reduces vibration and noise. A custom design ensures even quieter performance, which is crucial for applications in industries requiring silent or vibration-free environments.

Compact and Flexible Design

Customization allows for a compact footprint without compromising torque capacity. These gear reducers can be integrated into systems with limited installation space.

Durability and Long Service Life

Made with high-strength alloys and precision machining, custom reducers provide excellent wear resistance, heat dissipation, and long-lasting performance under continuous operation.

Custom Gear Ratios

With tailored gear ratios, the gearbox can precisely control speed reduction and torque multiplication according to the requirements of specific machinery.

Advantages in Motion Control Systems

Enhanced Efficiency: High transmission efficiency minimizes energy losses and improves system performance.

Reduced Maintenance Costs: Durable materials and precision engineering extend service life, lowering repair and replacement expenses.

Improved Positioning Accuracy: Smooth and stable gear engagement supports accurate motion control in sensitive applications.

Versatility Across Industries: Custom design ensures compatibility with various machinery, from conveyors to robotics.

Applications of Custom Helical Gear Reducers

Industrial Automation

Automation systems require precise and reliable motion control. Custom helical gear reducers deliver consistent torque and speed, ensuring smooth production processes.

Robotics and Handling Systems

Robots rely on compact, high-efficiency gear reducers for accurate movement. A custom solution allows integration into robotic joints, enabling precise and quiet operations.

Material Handling Equipment

Conveyors, elevators, and cranes depend on robust gear reducers to handle heavy loads efficiently. High torque capacity and durability make custom helical reducers an ideal choice.

Textile and Packaging Machinery

These industries need high-speed yet low-noise gear solutions. Custom helical reducers offer stable transmission and long service life in continuous-use environments.

Renewable Energy Systems

In wind and solar tracking systems, gear reducers must combine durability with efficiency. Custom designs adapt to environmental conditions while maintaining reliable performance.

Why Choose a Custom Helical Gear Reducer

Compared to standard gear reducers, a custom-engineered solution provides clear advantages:

Tailored Performance: Exact gear ratios, torque capacities, and dimensions to fit your machinery.

Optimized Integration: Custom reducers ensure compatibility with existing motors and systems, reducing downtime during installation.

Enhanced Reliability: Designed specifically for the load and operational conditions of your system, minimizing risk of failure.

Scalable Solutions: Whether for small precision machinery or large industrial equipment, customization ensures the right fit for any application.

Maintenance and Care Tips

To ensure long-term performance and reliability of a custom helical gear reducer, proper maintenance is essential:

Regular Lubrication: Maintain correct lubrication levels to reduce friction and wear.

Temperature Monitoring: Prevent overheating by keeping the reducer within recommended operating temperatures.

Periodic Inspections: Check gear alignment, seals, and bearings for early signs of wear.

Load Management: Avoid overloading the reducer to extend service life and prevent operational failures.

Conclusion

iHF Group custom helical gear reducer is a high-performance solution for industries requiring high torque, low noise, and reliable motion control. By combining the advantages of helical gear technology with tailored engineering, these reducers offer unmatched efficiency, durability, and versatility.

Whether applied in automation systems, robotics, material handling, or renewable energy, a custom gear reducer ensures optimized performance and long-term value. For manufacturers and engineers seeking to improve productivity and reliability, investing in a custom helical gear reducer is a step toward achieving seamless, efficient, and quiet power transmission.

EN

EN Request Quote

Request Quote