Find out more about our news >

Round Linear Guide Shaft Technology for High-Reliability Linear Systems

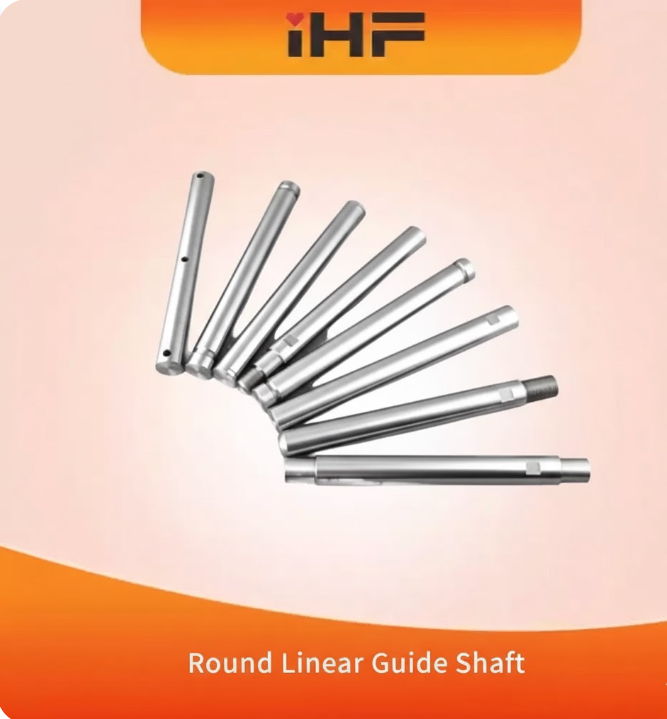

In the realm of precision engineering, the components that facilitate linear motion play a pivotal role in ensuring the reliability and accuracy of various systems. Among these components, the Round Linear Guide Shaft stands out as a fundamental element that supports a wide range of applications, from micro precision instruments to large industrial machinery.

The Core Functionality of Round Linear Guide Shafts

Round Linear Guide Shafts serve as the backbone of linear motion systems. They provide a smooth and stable path for linear bearings, which are essential for the movement of components in machinery. The design and manufacturing precision of these shafts are crucial, as they directly influence the performance and longevity of the entire system.

High-Precision Manufacturing

iHF Group's Round Linear Guide Shafts are manufactured to strict g6 high-precision tolerances. This level of precision ensures minimal clearance between the shaft and the linear bearings, resulting in smooth and efficient motion. The meticulous manufacturing process not only enhances performance but also reduces wear and tear, leading to a longer service life for the entire assembly.

Exceptional Surface Treatment

One of the standout features of iHF Group's Round Linear Guide Shafts is the Hard Chrome Plating applied to the shaft surface. This treatment achieves a maximum surface hardness of HRC 58, providing exceptional wear and corrosion resistance. Such durability is vital in environments where the shafts are exposed to harsh conditions, ensuring that they maintain their integrity and functionality over time.

Dimensional Flexibility for Diverse Applications

One of the key advantages of iHF Group's Round Linear Guide Shafts is their extensive dimensional flexibility. With a diameter range from 3mm to 50mm and customizable lengths from 10mm to 1500mm, these shafts can cater to a wide array of design requirements. This flexibility makes them suitable for various applications, including:

Micro Precision Instruments: In applications where space is limited and precision is paramount, smaller diameter shafts are ideal. They enable the creation of compact and efficient systems without compromising on performance.

Industrial Equipment: For larger machinery, the ability to customize lengths allows engineers to design systems that can handle significant loads and operate smoothly over extended distances.

Applications Across Industries

The versatility of Round Linear Guide Shafts makes them indispensable across multiple industries. Here are a few notable applications:

Automation and Robotics: In automated systems, precise linear motion is critical for tasks such as assembly, packaging, and material handling. Round Linear Guide Shafts ensure that robotic arms and other moving parts operate with accuracy and reliability.

Medical Devices: In the medical field, precision instruments must function flawlessly. Round Linear Guide Shafts are used in devices such as MRI machines and surgical robots, where accuracy can significantly impact patient outcomes.

CNC Machinery: Computer Numerical Control (CNC) machines rely on precise linear motion for cutting, milling, and engraving. The use of high-quality Round Linear Guide Shafts ensures that these machines deliver consistent and accurate results.

Why Choose iHF Group for Round Linear Guide Shafts

iHF Group is a professional supplier of precision linear motion components, focused on delivering reliable and application-ready solutions. Key strengths include:

Strict adherence to g6 precision tolerance

Advanced surface treatment capabilities

Broad dimensional customization options

Stable production and quality control systems

Engineering-oriented customer support

By combining precision manufacturing with practical design flexibility, iHF Group supports OEMs and system integrators in building high-performance linear motion systems.

Conclusion

The Round Linear Guide Shaft is far more than a simple mechanical rod—it is a precision-engineered component that defines the accuracy, durability, and efficiency of linear motion systems. From micro-scale instruments to large industrial equipment, its performance directly influences system reliability.

With high-precision manufacturing, hard chrome surface treatment, and extensive dimensional flexibility, solutions from iHF Group provide engineers and manufacturers with a dependable foundation for advanced motion design.

EN

EN Request Quote

Request Quote