Learn more >

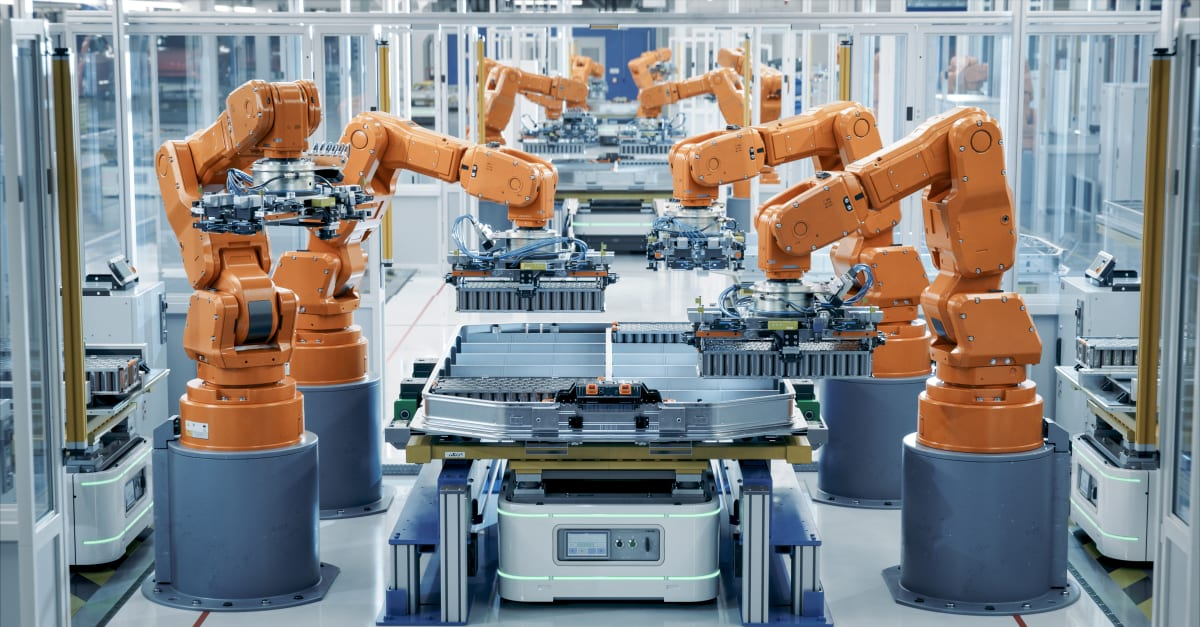

Planetary Reducers in Precision Rotary Die-Cutting: Enhancing Tension Control and Print Registration Accuracy Application Scenario

In the converting industry, a leading equipment manufacturer faced persistent challenges with their flagship 10-station rotary die-cutting machine. During high-speed operation, the machine exhibited subtle tension fluctuations in its unwind/rewind systems, resulting in material web instability. This caused inconsistent print registration accuracy and occasional material deformation, particularly when processing heavy paper rolls exceeding 800kg. The recurring issues led to increased waste rates and limited overall equipment effectiveness.

Technical Implementation

The engineering team identified the core issue resided in the dynamic response characteristics of the drive systems. After thorough evaluation, they integrated PX series planetary reducers into both the unwind and rewind stations, creating a synchronized drive solution.

The planetary reducers provided three critical performance enhancements:

1. Superior Torque Density The PX series delivered exceptional torque output relative to their compact size,enabling stable operation even under maximum load conditions. This high torque capacity maintained consistent web tension during acceleration, deceleration, and sudden operational changes.

2. Precision Motion Control With positioning accuracy within±1 arc-minute and near-zero backlash, the reducers enabled micron-level control of material advancement. This precision directly translated to improved registration accuracy, maintaining positional tolerances within ±0.1mm throughout production runs.

3. Dynamic Response Optimization The reducers'high torsional stiffness and optimized inertia matching allowed rapid response to tension control commands. This capability proved crucial in maintaining stable web tension during splice operations and sudden speed changes.

Performance Outcomes

Following the integration of PX planetary reducers, the die-cutting machine demonstrated remarkable improvements:

· Registration Accuracy: Improved from ±0.3mm to ±0.1mm consistency

· Web Tension Stability: Maintained within ±2% of set value during operation

· Maximum Operating Speed: Increased by 22% while maintaining quality standards

· Reject Rate: Reduced from 3.2% to 0.8% of production output

· Energy Consumption: Decreased by 18% due to improved transmission efficiency

Technical Differentiation

Unlike the previous drilling application that emphasized positional accuracy for discrete operations, this implementation highlights the PX series' capabilities in continuous process control. The reducers excel in dynamic tension management applications where maintaining constant web properties is critical throughout production cycles.

The solution demonstrates particular strength in handling the inherent challenges of converting applications:

· Managing large inertia variations during roll diameter changes

· Maintaining precise speed synchronization across multiple stations

· Providing smooth torque transmission without cogging or resonance issues

Conclusion

The successful implementation of PX series planetary reducers in this precision converting application underscores their versatility in addressing complex motion control challenges. By providing both the high torque capacity for heavy load handling and the precise control capabilities for delicate web management, these reducers enabled significant improvements in both quality metrics and operational efficiency.

This case study illustrates how advanced transmission technology can transform equipment performance in continuous process applications, particularly where both power transmission accuracy and dynamic response characteristics are critical to success.

Explore application possibilities: Our engineering team provides comprehensive technical support for integrating high-precision drive solutions into your specialized equipment.

EN

EN Request Quote

Request Quote