Find out more about our news >

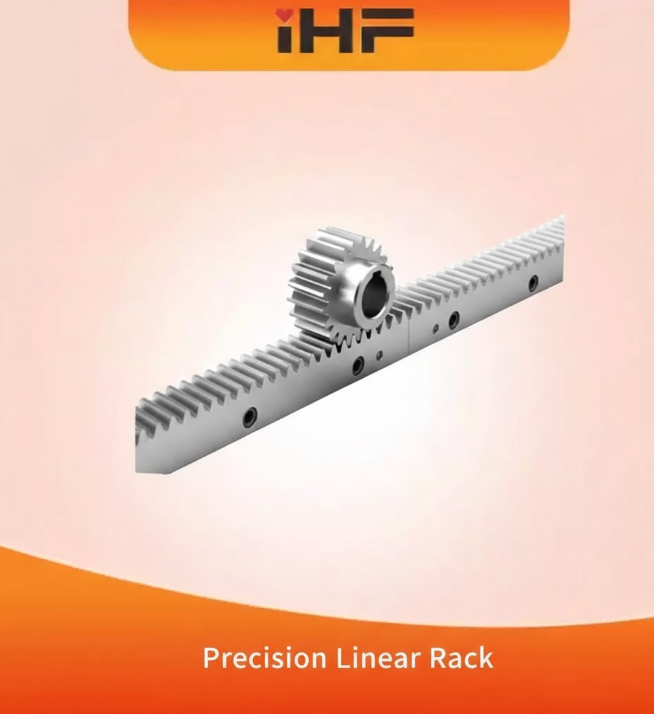

Elevating Performance: The Advantages of Precision Linear Racks in Industrial Applications

In modern automation and mechanical transmission systems, linear motion accuracy is no longer a secondary requirement—it is a defining parameter. Whether in CNC machine tools, automated assembly lines, or heavy-duty positioning systems, precision linear racks play a critical role in converting rotational motion into controlled, repeatable linear displacement.

Unlike standard racks designed for general-purpose motion, a precision linear rack is engineered with strict geometric tolerances, optimized tooth profiles, and material properties tailored for long-term reliability under load. At iHF Group, precision linear racks are developed as performance components rather than simple mechanical accessories.

1. The Role of Precision Linear Racks in Motion Control

A linear rack functions in conjunction with a pinion gear to translate rotary motion into linear movement. What differentiates a precision linear rack is its ability to maintain:

Consistent backlash control

Uniform load distribution along the tooth profile

Stable linear positioning accuracy over extended travel lengths

These characteristics are essential in systems where positioning error directly affects product quality, machining accuracy, or operational safety.

2. Standard Spur Rack Geometry: Why the 20° Pressure Angle Matters

The standard spur rack offered by iHF Group features a 20° pressure angle, a widely adopted geometry in high-precision gear systems.

Advantages of a 20° Pressure Angle

Higher load-carrying capacity compared to lower-angle designs

Improved tooth root strength, reducing the risk of fatigue failure

More stable meshing with pinions at high speeds

Better tolerance to minor misalignment

This geometry ensures smooth torque transmission while minimizing vibration and wear, particularly in demanding industrial environments.

3. Precision Manufacturing: Where Accuracy Is Engineered

Precision linear racks are not defined solely by design—they are defined by how accurately that design is manufactured.

At iHF Group, precision manufacturing focuses on:

Controlled tooth profile accuracy

Consistent pitch and straightness over the entire rack length

Surface finish optimization to reduce friction and noise

Precision machining and inspection processes ensure that the rack performs predictably when integrated into high-accuracy motion systems.

4. Material Selection: Performance Begins at the Metallurgical Level

Material choice directly impacts load capacity, wear resistance, and environmental suitability. iHF Group offers precision linear racks in two carefully selected materials, each optimized for specific operating conditions.

S45C Medium Carbon Steel

S45C is widely used in mechanical transmission due to its balanced mechanical properties.

Key advantages:

High strength and load-bearing capability

Excellent wear resistance after proper heat treatment

Suitable for high-load and high-duty-cycle applications

This material is ideal for machine tools, industrial automation, and heavy positioning systems where structural rigidity is essential.

SUS304 Stainless Steel

For environments where corrosion resistance is critical, SUS304 stainless steel provides a reliable alternative.

Key advantages:

Excellent resistance to corrosion and oxidation

Stable performance in humid or chemically exposed environments

Suitable for food processing, pharmaceutical, and clean-room applications

By offering both options, iHF Group enables engineers to match material performance precisely to operating conditions.

5. Load Capacity and Durability in Demanding Applications

Precision linear racks are often subjected to continuous load cycles, shock forces, and high-speed operation. A properly engineered rack must maintain dimensional stability under these conditions.

Key performance factors include:

Tooth surface hardness and wear resistance

Uniform load distribution across the rack length

Resistance to deformation under peak loads

The combination of optimized tooth geometry and high-quality materials allows precision linear racks to deliver long service life with minimal maintenance.

6. Application Scenarios for Precision Linear Racks

Precision linear racks are widely used across industries where accuracy and reliability are critical.

CNC Machine Tools

Used in axis positioning systems to achieve repeatable, micron-level accuracy over long travel distances.

Industrial Automation

Applied in robotic gantries, pick-and-place systems, and transfer units requiring synchronized linear motion.

Packaging and Assembly Lines

Enable precise positioning and timing in high-speed production environments.

Specialized Equipment

Ideal for systems operating in corrosive, humid, or clean-room environments when using SUS304 stainless steel racks.

Conclusion: Precision Linear Racks as a Performance Investment

A precision linear rack is not a commodity component—it is a critical element that defines motion accuracy, system reliability, and operational lifespan. From tooth geometry and pressure angle to material engineering and manufacturing precision, every detail contributes to performance.

By offering precision-manufactured spur racks with a proven 20° pressure angle and carefully selected material options, iHF Group provides solutions tailored to the real-world demands of modern industrial motion systems.

EN

EN Request Quote

Request Quote