Find out more about our news >

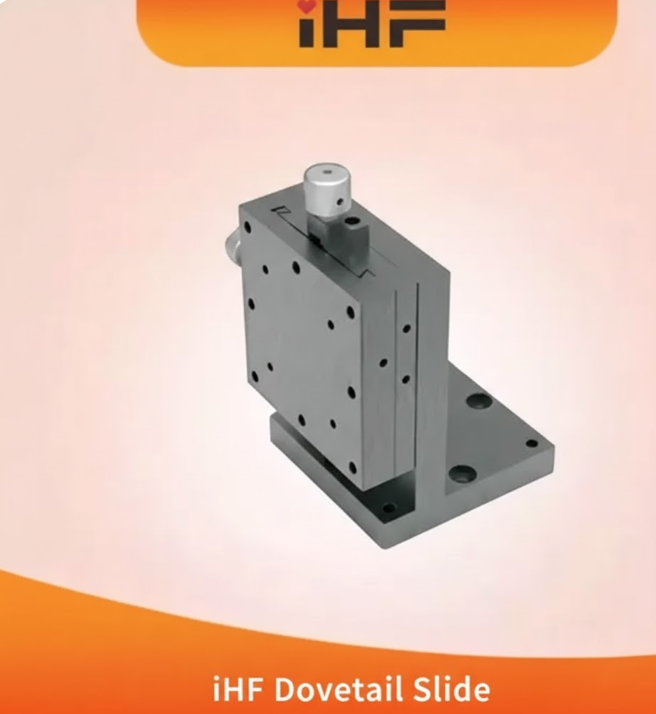

When Simplicity Wins: The Role of iHF Dovetail Slides in Industrial Motion

In industrial automation and mechanical systems, linear motion solutions are often evaluated through the lens of precision, rigidity, speed, and cost. While high-end linear guides and ball screw systems dominate applications requiring micron-level positioning, many industrial processes prioritize travel length, operational robustness, and fast adjustment over absolute accuracy.

This is where the iHF Dovetail Slide finds its optimal value proposition. Designed around a proven mechanical principle, dovetail slides offer smooth motion, structural simplicity, and cost efficiency, making them a practical choice for long-stroke and rapid-feeding applications. At iHF Group, dovetail slide systems are engineered to meet real-world industrial demands rather than theoretical performance extremes.

Core Working Principle: Interlocking Dovetail Guidance

The iHF Dovetail Slide operates on an interlocking inner and outer dovetail groove mechanism. Unlike rolling-element linear guides, this structure relies on sliding contact surfaces for guidance and motion.

Key mechanical characteristics include:

Stable linear guidance through geometric interlocking

High load-bearing contact area

Intrinsic resistance to lateral displacement

Predictable wear behavior under continuous operation

This guidance method ensures smooth and controlled movement, especially over extended travel ranges where rolling systems may face alignment or cost challenges.

Structural Advantages: Why Dovetail Slides Still Matter

Smooth Movement with Extended Travel

Dovetail slides are inherently well-suited for long-stroke motion. The absence of recirculating rolling elements reduces complexity, allowing for:

Longer uninterrupted travel lengths

Consistent motion behavior over distance

Reduced sensitivity to contamination

Simple Structure, High Reliability

With fewer internal components, the dovetail slide offers:

Lower failure risk

Easier maintenance

High mechanical robustness in industrial environments

This simplicity translates directly into lower lifecycle cost, a key reason why dovetail slides remain widely used in production machinery.

Cost-Effectiveness for Industrial Scale

Compared to precision linear guideways, dovetail slides provide a more economical solution when ultra-high positioning accuracy is not required. For OEMs and system integrators, this allows better cost control without sacrificing functional reliability.

Drive Type Configurations Offered by iHF Group

To accommodate diverse operational requirements, iHF Group provides dovetail slides with multiple drive mechanisms, each optimized for specific motion characteristics.

Rack and Pinion Drive

Rack and pinion systems are particularly advantageous for long-stroke dovetail slides.

Key benefits:

Unlimited or extended travel capability

Fast feeding speed

High mechanical durability

iHF Group offers multiple rack-and-pinion models specifically engineered for long-stroke applications, making them ideal for large-format equipment and rapid adjustment tasks.

Feed Screw Drive

Feed screw-driven dovetail slides provide:

Controlled manual or motorized adjustment

Moderate positioning repeatability

Compact integration

They are commonly used in fixtures, tooling setups, and adjustment mechanisms.

Lead Screw Drive

Lead screw drives balance simplicity and controllability, suitable for:

Light to medium load applications

Repetitive linear motion

Cost-sensitive automation solutions

Application Scenarios: Where iHF Dovetail Slides Excel

Rapid Feeding Operations

Dovetail slides perform reliably in systems requiring frequent, fast linear movement without the need for fine positional resolution.

Quick Adjustment Mechanisms

In tooling, clamping, and positioning fixtures, the ability to adjust quickly and lock securely is often more valuable than micron-level accuracy.

Long-Stroke Industrial Equipment

Large machinery, material handling systems, and auxiliary motion modules benefit from the extended travel capability of rack-and-pinion dovetail slides.

Important Design Consideration: Precision Limitations

While highly versatile, iHF Dovetail Slides are not recommended for applications requiring high-precision positioning.

Due to their sliding contact nature:

Friction is higher than rolling systems

Positioning repeatability is limited

Wear affects long-term accuracy

For applications demanding tight tolerances, ball screws or linear guide systems remain the preferred solution. iHF Group emphasizes correct application matching to ensure optimal system performance.

Why Choose iHF Group Dovetail Slide Solutions

iHF Group approaches dovetail slide design from a practical engineering perspective, focusing on:

Application-driven drive selection

Structural reliability over long travel

Cost-performance optimization

Consistent manufacturing quality

Rather than positioning dovetail slides as universal solutions, iHF Group provides purpose-built models aligned with industrial realities.

Conclusion: Practical Motion Engineering with iHF Dovetail Slides

In industrial motion systems, effectiveness is not defined solely by precision. For long-stroke, rapid-feeding, and adjustment-intensive applications, the iHF Dovetail Slide delivers a compelling combination of smooth motion, structural simplicity, and economic value.

By offering multiple drive types and specialized long-stroke designs, iHF Group ensures that dovetail slide systems remain a relevant and efficient solution in modern industrial machinery.

EN

EN Request Quote

Request Quote