Find out more about our news >

Maximizing Uptime: The Engineering Secrets Behind High-Performance Drag Chain Cable Carriers

In modern automation systems, motion is continuous, repetitive, and increasingly fast. Linear axes, gantry systems, CNC machines, and robotic arms all rely on uninterrupted power, signal, and fluid transmission. Yet, one of the most common causes of machine failure is not motors or controllers—but damaged cables.

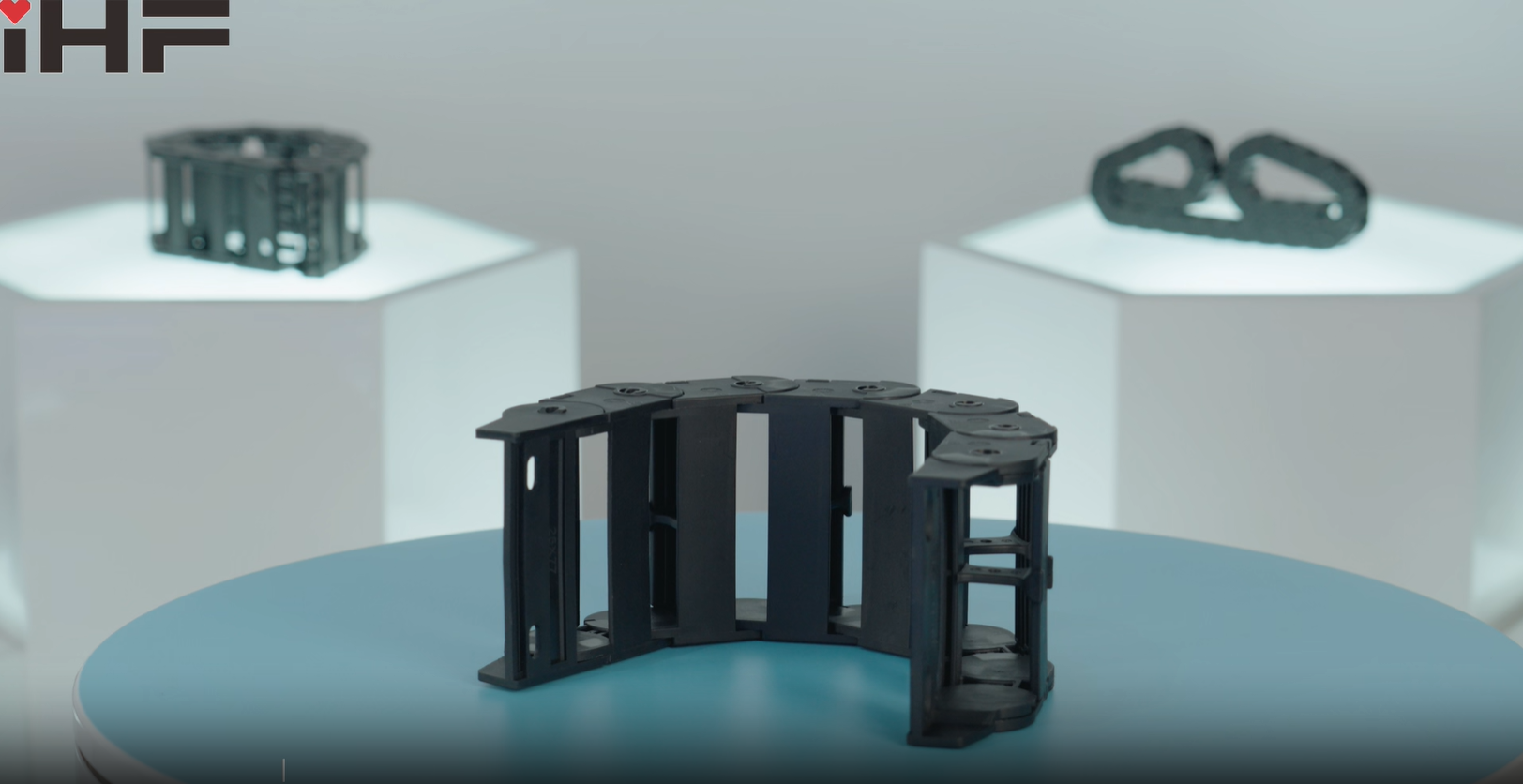

This is where the drag chain cable carrier plays a decisive role. Far from being a passive accessory, it is a functional mechanical system designed to protect cables and hoses during dynamic motion. Companies such as iHF Group engineer drag chain cable carriers to meet the real-world demands of industrial automation, where reliability and uptime are critical.

Functional Role of a Drag Chain Cable Carrier

A drag chain cable carrier guides moving cables along a predefined path, ensuring controlled bending and eliminating random movement. Its core functions include:

Maintaining a fixed minimum bending radius

Preventing abrasion and torsion

Organizing multiple cables and hoses in confined spaces

By controlling cable motion, drag chains significantly extend cable service life and reduce unplanned downtime.

Structural Engineering Behind High-Performance Drag Chains

1. Link Design and Mechanical Stability

Each link in a drag chain cable carrier must articulate smoothly while supporting the total load of cables. High-quality designs feature:

Precision-molded or machined hinge points

Balanced load distribution across the chain length

Resistance to deformation under continuous stress

iHF Group applies strict dimensional tolerances to ensure consistent articulation and stable motion, even at high speeds.

2. Material Selection Based on Application Conditions

Material choice directly impacts durability and performance. Common options include:

Reinforced polymer drag chains for lightweight, corrosion-resistant applications

Steel or stainless steel drag chains for heavy loads, high temperatures, or abrasive environments

Selecting the appropriate material ensures the carrier performs reliably throughout its intended service life.

Performance Benefits in Industrial Environments

Reduced Cable Fatigue and Replacement Costs

Repeated uncontrolled bending is the primary cause of cable failure. A properly selected drag chain cable carrier distributes bending stress evenly, reducing conductor fatigue and insulation damage.

Improved Machine Uptime

Cable failures often cause sudden and costly shutdowns. By protecting cables and hoses, drag chains contribute directly to higher equipment availability and more predictable maintenance schedules.

Cleaner System Integration

Organized cable routing improves machine layout, simplifies troubleshooting, and enhances overall system safety—especially in high-density automation environments.

Application Scenarios That Demand Drag Chain Cable Carriers

Drag chain cable carriers are widely used across industrial sectors, including:

CNC machining centers and milling machines

Automated assembly and packaging lines

Robotic arms and Cartesian systems

Material handling and logistics equipment

Each application presents different requirements for travel distance, speed, load capacity, and environmental resistance.

Key Engineering Criteria for Selecting a Drag Chain Cable Carrier

1. Load and Fill Ratio

Overloading or overfilling a drag chain increases internal friction and accelerates wear. Best practice is to limit the internal fill ratio to approximately 60% of available space.

2. Travel Length and Support Method

Long travel applications may require glide surfaces or roller-supported drag chains to reduce friction and noise. Proper support design prevents sagging and uneven wear.

3. Environmental Factors

Exposure to dust, coolant, chemicals, or extreme temperatures must be considered. Specialized materials and closed-link designs can significantly improve performance in harsh environments.

Installation Discipline and Maintenance Strategy

Even a well-designed drag chain cable carrier will underperform if installed incorrectly. Critical installation practices include:

Separating power and signal cables to avoid interference

Securing cables with proper strain relief

Maintaining smooth transitions at fixed and moving ends

Routine inspection for wear, contamination, or misalignment helps preserve long-term reliability.

Customization as a Technical Advantage

Standard drag chain sizes do not fit every application. Custom solutions may include:

Non-standard widths or heights

Integrated dividers and separators

Special materials for extreme duty cycles

iHF Group provides engineering-level customization to ensure drag chain systems align precisely with customer equipment and operating conditions.

Conclusion

The drag chain cable carrier may occupy a small footprint within a machine, but its impact on reliability, safety, and operating cost is substantial. By controlling motion, protecting cables, and reducing mechanical stress, it enables automation systems to operate continuously and efficiently.

Partnering with an experienced manufacturer like iHF Group ensures that this critical component performs exactly as intended—supporting productivity today and system longevity tomorrow.

EN

EN Request Quote

Request Quote