Find out more about our news >

Reducing Friction and Misalignment: The Technical Advantage of Self Aligning Linear Ball Bearings

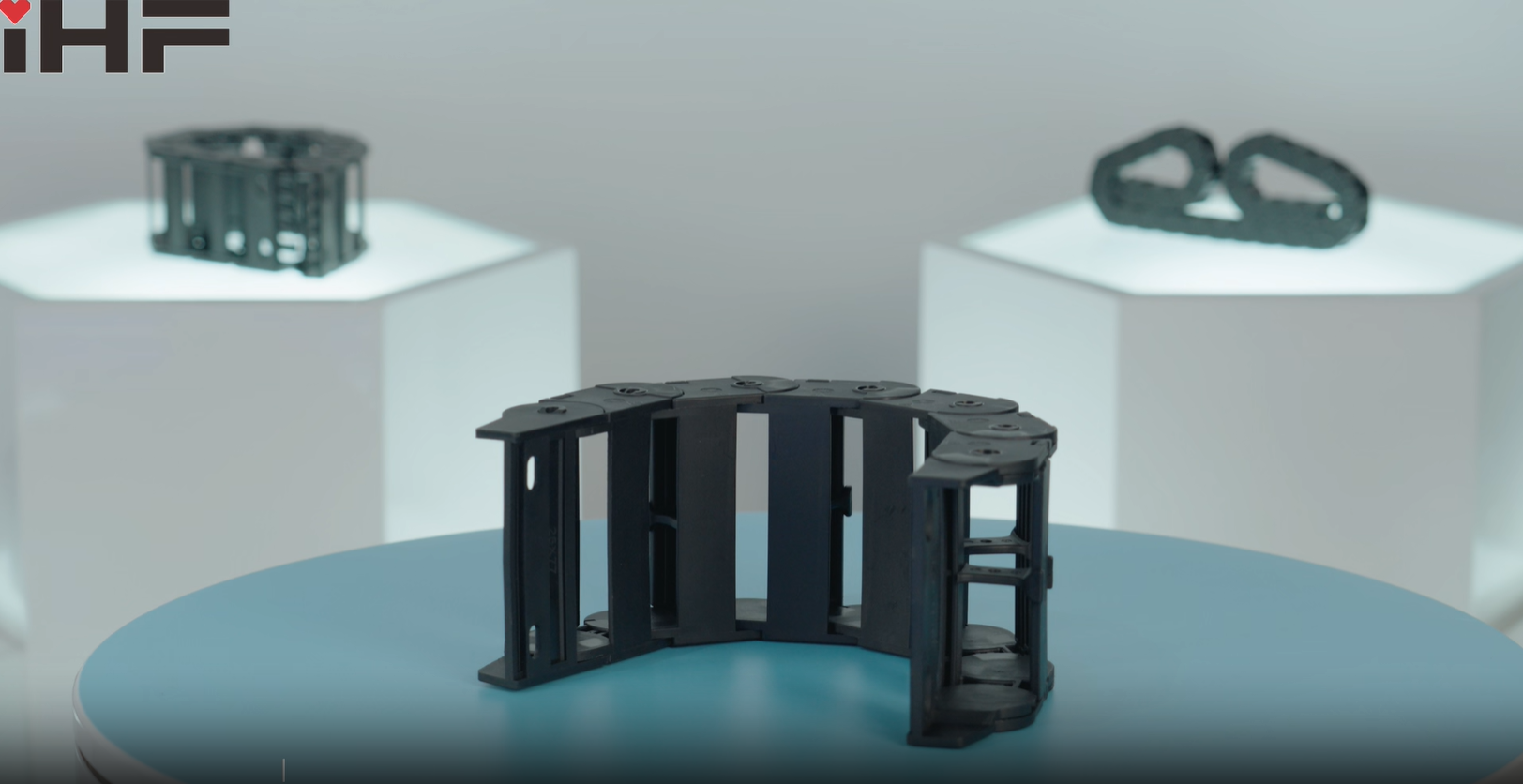

In today’s era of high-speed automation and precision engineering, even the smallest mechanical component can have a major impact on system performance. Among these critical components, the self aligning linear ball bearing stands out as a cornerstone for achieving smooth, precise, and durable linear motion. Whether it’s in CNC machinery, robotics, medical devices, or industrial automation systems, these bearings provide the perfect blend of flexibility and accuracy — allowing for superior load distribution and extended equipment life.

At iHF Group, we specialize in the research, design, and production of advanced linear motion components engineered to meet the rigorous standards of global manufacturers. Our self aligning linear ball bearings are built for engineers who demand consistent precision under dynamic conditions.

What Makes Self Aligning Linear Ball Bearings Different

Traditional linear bearings are designed for strict alignment between the shaft and housing. However, in real-world applications, even slight misalignments can occur due to installation errors, structural deformation, or thermal expansion. Such deviations often lead to increased friction, vibration, and premature wear.

The self aligning linear ball bearing, by contrast, features an internal spherical seat or floating design that automatically compensates for angular misalignments between the shaft and bearing block. This intelligent self-alignment mechanism ensures that the balls maintain even contact with the raceway, thereby minimizing friction and preventing localized stress.

In other words, self aligning linear ball bearings offer a forgiving yet highly precise motion system — one that adapts to its environment instead of fighting it.

Key Advantages of Self Aligning Linear Ball Bearings

Automatic Misalignment Compensation

These bearings can compensate for angular deviations of up to several degrees, ensuring consistent load distribution even under imperfect alignment.

Enhanced Service Life

The optimized load sharing reduces surface fatigue and prevents micro-spalling, extending bearing lifespan significantly compared to conventional designs.

Low Friction and Smooth Operation

The precision-ground ball tracks and self-aligning mechanism maintain optimal contact angles, resulting in smooth, quiet, and efficient movement.

Reduced Maintenance Costs

Because alignment errors are naturally compensated, installation becomes easier and less dependent on precision machining or adjustments — saving both time and cost.

Versatile Application Range

From high-speed automation lines to heavy-duty industrial presses, these bearings perform reliably across diverse environments and load conditions.

Engineering Applications Across Industries

At iHF Group, our self aligning linear ball bearings have been successfully implemented across multiple industrial sectors:

Robotics and Automation Systems: Ensuring stable and precise motion control even when arm structures deform slightly under load.

CNC and Machine Tools: Providing consistent linear guidance for spindles, slides, and cutting heads, even in thermally dynamic environments.

Packaging and Printing Machinery: Maintaining motion accuracy and stability despite frequent start-stop operations and vibration.

Medical Equipment: Supporting the smooth, noise-free motion required in diagnostic and surgical automation systems.

Semiconductor and Electronics Manufacturing: Allowing ultra-precise movement in contamination-sensitive environments.

In each of these industries, the unique self-aligning capacity reduces downtime, improves product consistency, and increases machine reliability.

Installation and Maintenance Insights

While self aligning linear ball bearings simplify alignment challenges, proper installation still enhances performance longevity. iHF Group recommends:

Ensuring shaft surface roughness and straightness meet bearing specifications.

Applying appropriate lubrication — typically lithium-based or synthetic greases — to minimize rolling friction.

Avoiding excessive preload, which can hinder the self-aligning movement.

Conducting periodic inspections for contamination, lubrication integrity, and wear.

Following these best practices ensures optimal functionality and maximum service life.

Conclusion: Precision That Adapts

In the world of linear motion, true precision is not just about tolerances — it’s about adaptability. The self aligning linear ball bearing embodies this philosophy by maintaining smooth, accurate, and reliable movement even under real-world imperfections.

Through continuous innovation and engineering excellence, iHF Group delivers motion solutions that empower manufacturers to achieve superior performance, reduced downtime, and long-term operational stability. Whether in automation, robotics, or advanced machinery, iHF Group bearings ensure that every movement counts.

EN

EN Request Quote

Request Quote