Send Inquiry Now

EN

EN

Request Quote

Request Quote

-

Name:

-

*Company Name:

-

*Email:

-

Motor Model:

-

Motor Power:

-

Gear Ratio:

-

Precision Requirement:

-

Motor Drawing:

-

Select Model Now:

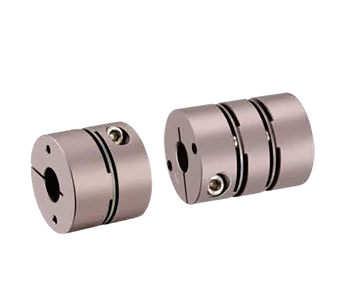

iHF CNC Machine Parts Aluminium Coupling with Double Diaphragm

Product features:

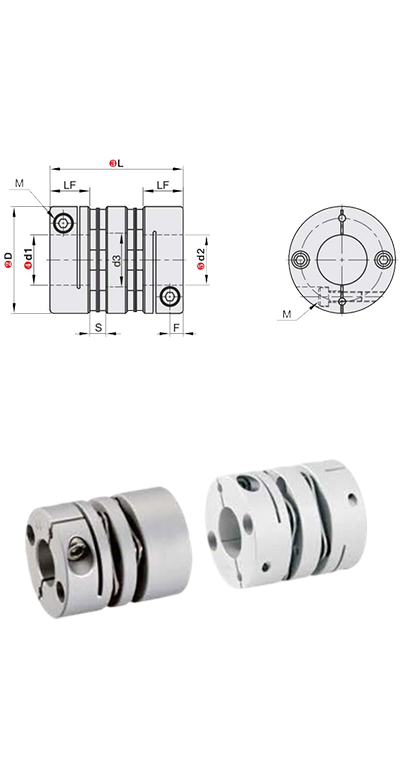

Double Diaphragm Short Clamping Type Aluminum Alloy Diaphragm Coupling

1.Material

- Hub: High-strength aluminum alloy

- Diaphragm: 304 stainless steel

2.Performance

- High torsional rigidity for precise shaft rotation control

- Extended design for effective radial, angular, and axial misalignment compensation

- Zero-backlash hub-shaft connection for bidirectional operation

- Low inertia suitable for high-speed applications

3.Design Features

- Optimized for servo/stepper motor integration

- Clamping screw fastening method

4.Key Applications

- High-precision motion control systems

- Industrial automation equipment

- Robotics and CNC machinery

| Model | L | Allowable Torque (N·m) | Allowable Misalignment (Radial) (mm) | Allowable Angular Misalignment (<°) | Allowable Axial Displacement (mm) | Maximum Allowable Speed (RPM) | Static Torsional Stiffness (N.m/rad) | Moment of Inertia (N.m) | Coupling Weight (g) | |

| Type | D | |||||||||

| QLDAW | 19 | 24.5 | 1 | 0.12 | 1.5 | ±0.18 | 10000 | 500 | 8.19×10-6 | 13.2 |

| 26 | 30 | 1.5 | 0.15 | 1.5 | ±0.30 | 10000 | 1850 | 1.7×10-6 | 32 | |

| 32 | 38 | 3 | 0.17 | 1.5 | ±0.36 | 10000 | 2850 | 7.6×10-5 | 58 | |

| 34 | 38 | 3 | 0.17 | 1.5 | ±0.36 | 10000 | 4050 | 9.0×10-5 | 71 | |

| 39 | 47 | 6 | 0.22 | 1.5 | ±0.45 | 10000 | 9000 | 2.7×10-5 | 110 | |

| 44 | 47 | 9 | 0.22 | 1.5 | ±0.54 | 10000 | 10000 | 3.8×10-5 | 134 | |

| 50 | 53 | 16 | 0.23 | 1.5 | ±0.68 | 10000 | 16000 | 4.2×10-5 | 225 | |

| 56 | 57 | 25 | 0.27 | 1.5 | ±0.72 | 10000 | 25000 | 1.14×10-4 | 298 | |

| 68 | 68 | 60 | 0.31 | 1.5 | ±0.8 | 10000 | 35000 | 1.8×10-4 | 472 | |

| 82 | 87 | 80 | 0.55 | 1.5 | ±0.8 | 10000 | 70000 | 2.25×10-4 | 983 | |

The inner bores on both ends of the coupling can be freely combined between minimum and maximum diameters, machined to H7 standard tolerance. Bore dimensions listed in tables are for reference only; for custom bore requirements, please contact our customer support, sales representatives, or technical personnel for detailed parameters.

| Model | L | d1,d2 (Keyway bore diameters are selectable for sizes above 6mm.) | LF | φd3 | S | F | M | Fastening Torque (N.m) | |

| Type | D | Double Diaphragm | |||||||

| QLDAW | 19 | 24.5 | 3 4 5 6 6.35 7 8 | 9.1 | 9 | 1.8 | 3.3 | M2.5 | 0.8 |

| 26 | 30 | 5 6 6.35 7 8 9 9.525 10 11 12 12.7 14 | 10.6 | 15 | 2.6 | 3.9 | M3 | 1.2 | |

| 32 | 38 | 5 6 6.35 7 8 9 9.525 10 11 12 12.7 14 15 | 12.25 | 15.5 | 3.5 | 3.85 | M3 | 1.2 | |

| 34 | 38 | 5 6 6.35 7 8 9 9.525 10 11 12 12.7 14 15 16 | 12.25 | 16.5 | 3.5 | 4.85 | M4 | 2.5 | |

| 39 | 47 | 6 8 9 9.525 10 11 12 12.7 14 15 16 17 18 19 | 14.9 | 19.3 | 4.4 | 5 | M4 | 2.5 | |

| 44 | 47 | 6 8 9 9 9.525 10 11 12 12.7 14 15 16 17 18 19 20 22 | 14.9 | 22.5 | 4.5 | 5 | M4 | 2.5 | |

| 50 | 53 | 6 8 9 9.525 10 11 12 12.7 14 15 16 17 18 19 25 28 30 32 | 18.1 | 26 | 4.8 | 5.8 | M5 | 5.0 | |

| 56 | 57 | 12 14 15 16 17 18 19 20 22 24 25 28 30 32 | 19.75 | 32.5 | 5.5 | 6.4 | M5 | 5.0 | |

| 68 | 68 | 16 17 18 19 20 22 24 25 28 30 32 35 38 | 23.35 | 38.3 | 6.3 | 7.7 | M6 | 8.0 | |

| 82 | 87 | 17 18 19 20 22 24 25 28 30 32 35 38 40 42 | 30 | 45.5 | 8 | 9.7 | M8 | 20 | |

The moment of inertia and all technical parameters provided are measured with the maximum bore size as the reference standard. The maximum rated torque correlates directly with the coupling's fatigue life. Larger outer diameters increase load capacity, while smaller outer diameters permit higher maximum allowable speeds.

| Model | Type | Material | Surface Treatment | Accessories | ||

| Housing | Diaphragm | |||||

| QLDAW | Double Diaphragm | Short Clamping Type | Aluminum Alloy | Stainless Steel | Anodized | Socket Head Cap Screw(SHCS) |

-

*

-

*

-

*

-

-