Find out more about our news >

Optimized Motion Control: The Advantage of Stepper Motor Gearbox Nema 23

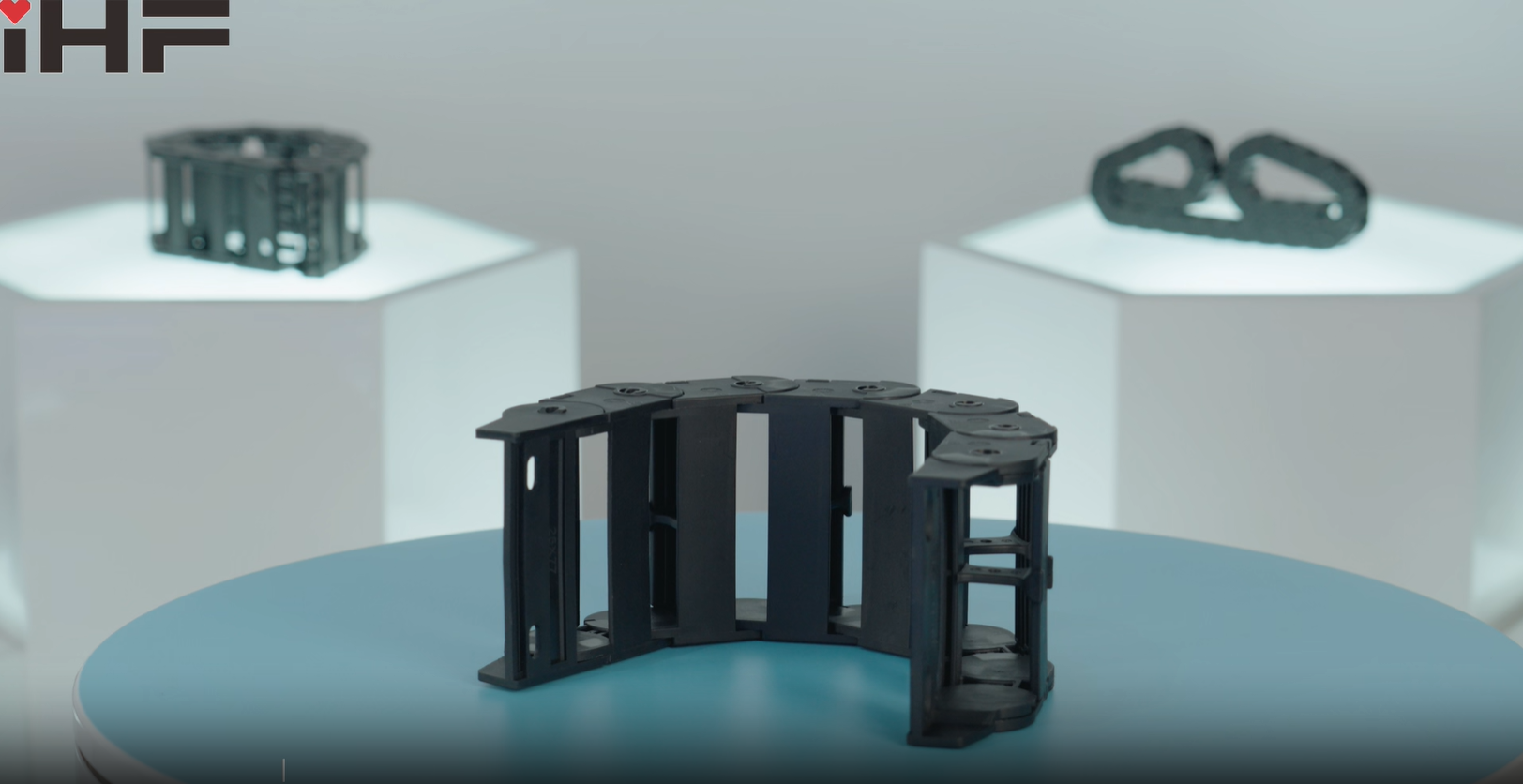

In the ever-evolving landscape of industrial automation and precision machinery, motion control remains a cornerstone of innovation. Among the numerous components driving performance and efficiency, the Stepper Motor Gearbox NEMA 23 stands out as a crucial element in achieving superior control, torque, and positioning accuracy. With a growing demand for compact yet powerful motion solutions, companies like iHF Group continue to lead the way by integrating cutting-edge engineering and design into every motor and gearbox they produce.

1. Understanding the Stepper Motor Gearbox NEMA 23

A Stepper Motor Gearbox NEMA 23 combines the precise control of a stepper motor with the torque amplification and speed reduction benefits of a gearbox. The NEMA 23 standard defines the motor’s frame size—2.3 inches (58.4 mm)—making it one of the most widely adopted sizes in robotics, CNC machinery, and industrial automation systems.

The gearbox, mounted to the stepper motor, not only enhances torque output but also allows for finer control over rotational movement. This combination enables engineers and machine builders to design systems that require accurate positioning, repeatability, and reliability without sacrificing performance.

2. Why Choose a NEMA 23 Stepper Motor Gearbox

The Stepper Motor Gearbox NEMA 23 offers a balance between compact size and high torque performance, making it ideal for medium-duty applications. Whether in 3D printers, packaging machines, or automation conveyors, this configuration ensures smooth and stable operation.

Key advantages include:

Enhanced Torque Output: The integrated gearbox increases the effective torque, allowing the motor to handle heavier loads with minimal slippage.

Improved Position Accuracy: Gear reduction enables finer control, which is essential for precise automation and robotics tasks.

Energy Efficiency: With better torque at lower speeds, energy consumption is reduced—important for systems requiring continuous operation.

Durability: High-quality materials and precision gear designs ensure long service life, even under demanding industrial conditions.

For manufacturers aiming to boost operational efficiency, the NEMA 23 Stepper Motor Gearbox delivers both reliability and versatility across various environments.

3. Applications Across Multiple Industries

The Stepper Motor Gearbox NEMA 23 is a favorite among engineers due to its adaptability across a wide range of applications. Some of the most common include:

CNC Machinery: Ensures smooth motion control and exact cutting paths.

3D Printers: Provides stable layer-by-layer motion for precise printing results.

Packaging Equipment: Enables accurate, repeatable movement for automated sealing and labeling processes.

Robotics: Delivers precision control for robotic arms and assembly systems.

Medical Devices: Offers quiet and smooth operation for laboratory instruments.

In each case, the NEMA 23 stepper motor gearbox enhances system stability, ensuring the machine operates efficiently, quietly, and with high repeatability.

4. iHF Group: Engineering Precision for the Future

At iHF Group, innovation in motion control technology is driven by precision engineering and quality assurance. With years of experience in producing high-performance stepper motors, gearboxes, and automation components, iHF Group’s mission is to provide reliable motion solutions tailored to customer needs.

Each Stepper Motor Gearbox NEMA 23 produced by iHF Group undergoes strict performance testing to ensure consistent torque, minimal backlash, and long-term stability. By combining advanced design software, high-grade materials, and automated production systems, iHF Group ensures every product exceeds industrial standards.

Furthermore, iHF Group’s technical team collaborates closely with clients to deliver custom motion control solutions, helping optimize system performance for different industrial applications. From prototype development to large-scale manufacturing, iHF Group delivers value through precision, reliability, and innovation.

5. Why iHF Group Is Your Trusted Motion Partner

Choosing the right Stepper Motor Gearbox NEMA 23 supplier means choosing performance, reliability, and technical expertise. iHF Group offers:

Comprehensive customization options for torque, gear ratios, and mounting styles.

Reliable after-sales support with quick response and professional technical guidance.

Strict quality assurance across every production stage.

Global logistics support ensuring timely delivery and continuous supply.

For engineers, integrators, and manufacturers who value long-term performance and dependability, iHF Group remains a trusted name in precision motion control technology.

Conclusion

In an era where automation drives productivity, the Stepper Motor Gearbox NEMA 23 represents the perfect fusion of power, precision, and reliability. Designed for a wide range of industrial applications, it enables efficient and accurate motion control while optimizing system performance. Backed by the innovation and engineering excellence of iHF Group, these systems are setting the standard for the next generation of motion control technology.

EN

EN Request Quote

Request Quote