Find out more about our news >

Maximizing Efficiency with iHF Linear Ball Slides: A Comprehensive Guide

In modern industrial automation and precision machinery, linear motion systems are no longer auxiliary components—they are core performance drivers. Positioning accuracy, load stability, repeatability, and service life are directly influenced by the quality of the linear guide system selected.

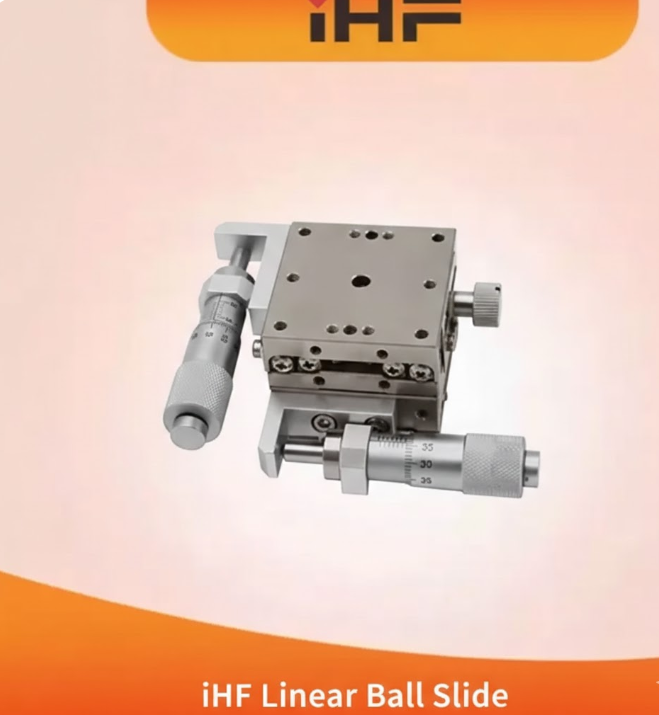

Among advanced linear motion solutions, the iHF Linear Ball Slide has emerged as a reliable option for engineers who demand low friction, high load capacity, and long-term dimensional stability. Designed for demanding industrial environments, this system bridges the gap between precision guidance and robust mechanical endurance.

With deep expertise in linear motion technologies, iHF Group continues to develop linear ball slide solutions that meet the evolving requirements of automation, machine tools, and high-speed equipment.

What Defines an iHF Linear Ball Slide

At a fundamental level, a linear ball slide is a rolling-element guidance system that uses recirculating steel balls between a rail and carriage to minimize friction while maintaining precise linear movement.

The iHF Linear Ball Slide is engineered with the following core characteristics:

Optimized raceway geometry for smooth ball circulation

High-strength bearing steel rails with precision grinding

Controlled preload options to balance rigidity and smoothness

Modular carriage designs for flexible system integration

Unlike plain linear bearings, linear ball slides significantly reduce sliding friction, resulting in higher efficiency, reduced wear, and improved positional accuracy.

Mechanical Performance Advantages

1. Low Friction and Energy Efficiency

Rolling contact between the balls and raceways reduces friction coefficients to a fraction of those found in sliding systems. This directly translates into:

Lower drive torque requirements

Reduced heat generation

Improved system responsiveness

For servo-driven or high-speed applications, these characteristics are essential for maintaining dynamic accuracy.

2. High Load Capacity and Structural Rigidity

The iHF Linear Ball Slide is designed to support multi-directional loads, including radial, reverse radial, and lateral forces. Load distribution across multiple rows of balls allows the system to handle:

High static and dynamic loads

Moment loads from offset forces

Continuous operation under vibration

This makes the system suitable for heavy-duty automation platforms and industrial machinery.

3. Precision and Repeatability

Precision-ground rails and carriages ensure consistent linear accuracy over long travel distances. With appropriate installation and alignment, the iHF Linear Ball Slide delivers:

High positioning repeatability

Stable motion under variable speeds

Minimal backlash and play

These attributes are critical in CNC machinery, inspection systems, and robotic axes.

Design Considerations When Selecting an iHF Linear Ball Slide

Selecting the correct linear ball slide involves more than matching load ratings. Engineers must consider:

Load direction and moment distribution

Required travel length and stroke

Operating speed and acceleration

Environmental factors such as dust, moisture, or temperature

iHF Group supports customers with technical guidance to ensure that each linear ball slide configuration aligns with real-world operating conditions, not just catalog values.

Typical Industrial Applications

Automation & Assembly Lines

Linear ball slides enable fast, repeatable positioning of components, improving throughput and reducing cycle times.

Machine Tools

In milling, drilling, and grinding machines, precise linear guidance directly impacts surface finish and dimensional accuracy.

Robotics & Cartesian Systems

Linear ball slides provide stable and smooth motion for robotic arms, gantries, and pick-and-place systems.

Semiconductor & Electronics Equipment

Low vibration and high repeatability make iHF Linear Ball Slides suitable for clean and precision-sensitive environments.

Durability, Lubrication, and Maintenance

Long service life is a defining advantage of high-quality linear ball slides. The iHF Linear Ball Slide incorporates:

Optimized lubrication paths

Sealing options to prevent contamination

Wear-resistant raceway materials

Proper lubrication intervals and installation practices significantly extend operational life, even under continuous-duty cycles.

Integration and Customization Flexibility

Modern machinery often requires tailored solutions. The iHF Linear Ball Slide supports:

Multiple rail sizes and carriage types

Preload customization for rigidity control

Compatibility with standard mounting interfaces

This flexibility allows system designers to integrate linear ball slides seamlessly into both new designs and retrofits.

Conclusion: Precision That Moves Industry Forward

The iHF Linear Ball Slide represents a refined balance between precision engineering and industrial durability. By combining optimized rolling mechanics, robust materials, and application-driven design, it delivers reliable linear motion in environments where accuracy and consistency are non-negotiable.

Backed by technical expertise and manufacturing excellence, iHF Group continues to provide linear motion solutions that support modern automation, advanced machinery, and high-performance industrial systems.

EN

EN Request Quote

Request Quote