Find out more about our news >

Stepper Planetary Gearbox Solutions for Precise Positioning

In the world of modern automation, robotics, and motion control, precision and reliability are key. Industries such as manufacturing, aerospace, medical devices, and semiconductor production require systems that can deliver consistent and accurate positioning, often under high load conditions. One of the most effective solutions to achieve this is the stepper planetary gearbox. By combining the efficiency of a planetary gear system with the accuracy of stepper motors, manufacturers gain a powerful tool to optimize motion systems and enhance overall productivity.

What is a Stepper Planetary Gearbox

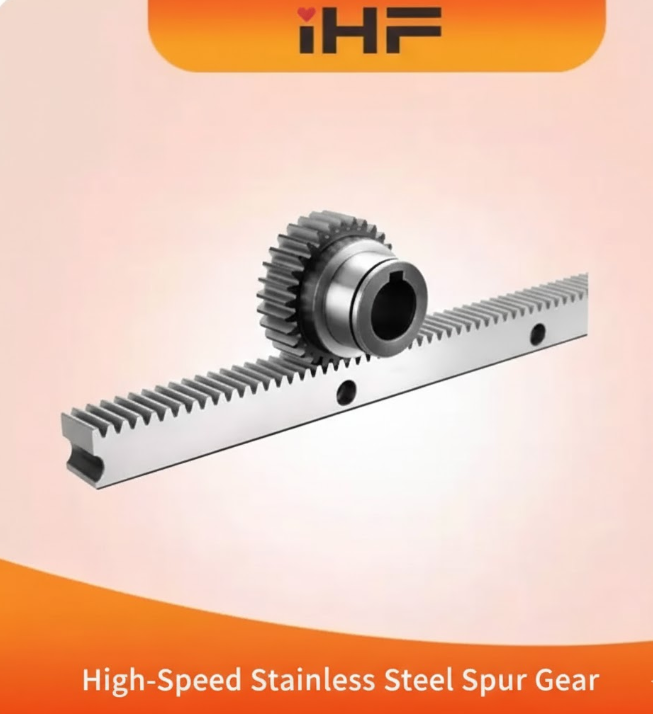

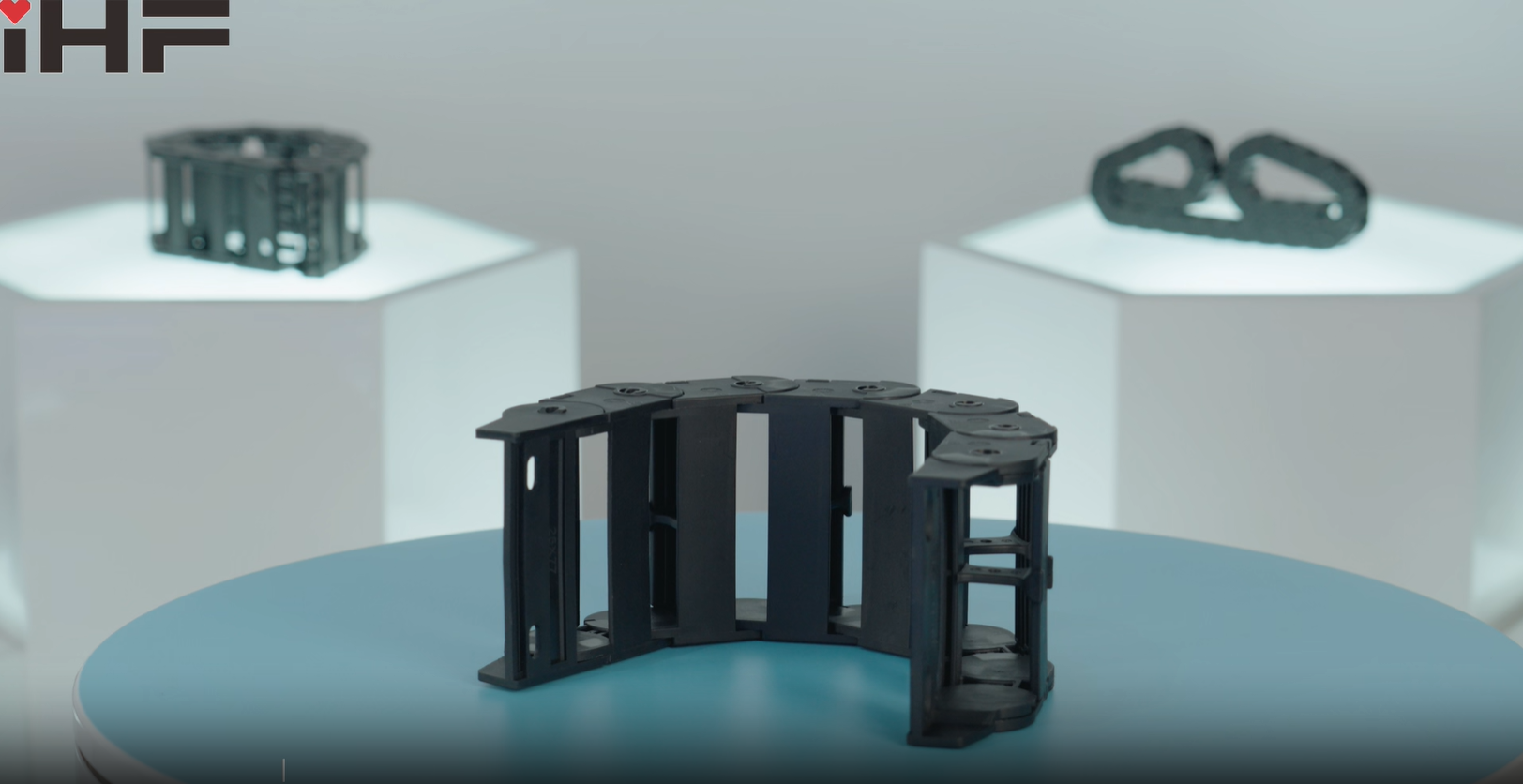

A iHF Group stepper planetary gearbox integrates a planetary gear mechanism with a stepper motor to provide controlled torque transmission and precise motion. The planetary gearbox uses a central sun gear, surrounding planet gears, and an outer ring gear. This configuration allows torque to be distributed evenly, ensuring smooth motion and high load capacity within a compact design.

When paired with a stepper motor, the gearbox enables controlled step-by-step positioning while reducing motor speed and amplifying torque. This makes it an ideal choice for applications that demand both accuracy and power.

Advantages of Stepper Planetary Gearbox Solutions

1. High Precision and Positioning Accuracy

The stepper motor provides incremental movement, while the gearbox reduces backlash and enhances repeatability. This ensures precise positioning, critical for robotics, CNC machines, and semiconductor equipment.

2. Compact Design with High Torque Output

Planetary gearboxes are known for their compactness and efficiency. By transmitting torque through multiple contact points, they achieve higher torque density in a smaller footprint, ideal for space-constrained machinery.

3. Low Backlash for Smooth Operation

In motion control systems, backlash can negatively affect accuracy. High-quality stepper planetary gearboxes are engineered with low-backlash designs, ensuring smoother and more reliable performance.

4. Energy Efficiency

By reducing the motor speed while increasing torque, the system consumes less energy and extends the motor’s lifespan, offering both performance and cost benefits.

5. Durability and Reliability

Constructed with hardened gears and robust housings, planetary gearboxes provide long-lasting performance, even under continuous heavy-duty applications.

Applications of Stepper Planetary Gearboxes

The versatility of these gearboxes makes them suitable for a wide range of industries and applications:

Robotics – For precise joint movement and smooth control in robotic arms and automated guided vehicles (AGVs).

CNC Machinery – To achieve accurate cutting, milling, and drilling with minimal error.

Medical Equipment – In imaging systems and surgical robotics, where exact positioning is crucial.

Aerospace and Defense – For reliable motion control in navigation, surveillance, and testing systems.

Packaging and Automation – Delivering accurate movement for conveyors, labeling machines, and pick-and-place systems.

Key Features of Stepper Planetary Gearboxes

Multiple Gear Ratios Available – Offering flexibility to match speed and torque requirements.

Low Noise Operation – Precision engineering ensures quiet performance, ideal for sensitive environments.

High Load Capacity – With multiple gears sharing the load, these gearboxes withstand heavy stress.

Customizable Designs – Tailored to meet specific industry needs, including compact or high-torque versions.

Seamless Integration – Compatible with different stepper motor models and control systems.

Sustainability and Efficiency Benefits

In addition to performance, stepper planetary gearboxes support sustainability goals:

Energy Savings – Lower energy consumption due to optimized torque transmission.

Extended Equipment Life – Reduced wear on motors results in fewer replacements and lower maintenance costs.

Reduced Material Waste – Consistent precision ensures fewer defective products in manufacturing.

Conclusion

A stepper planetary gearbox is more than just a mechanical component—it is the backbone of precision motion systems. By combining high torque, low backlash, and compact design, it enables industries to achieve consistent accuracy and reliability in demanding applications. From robotics to CNC machining, medical devices to aerospace systems, these gearboxes provide unmatched solutions for precise positioning and long-term efficiency.

Investing in iHF Group stepper planetary gearbox solutions not only boosts performance but also supports sustainable and cost-effective manufacturing practices. For businesses aiming to stay competitive in today’s high-tech industries, adopting advanced gearbox systems is a crucial step toward success.

EN

EN Request Quote

Request Quote