Send Inquiry Now

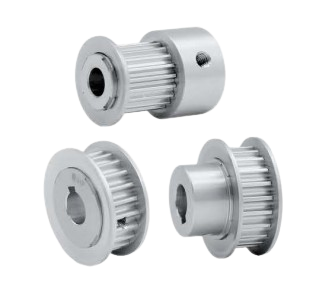

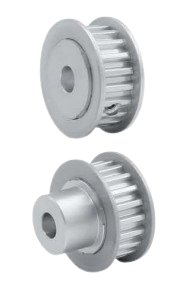

iHF Timing belt Pulley High Precision Positioning 2GT 3GT 5GT 8YU

Productfeatures:

High-Precision Positioning – The pulley system features zero-backlash drive, ensuring tight tooth engagement with the belt. This eliminates backlash during forward and reverse motion, enhancing positioning accuracy.

Stable Synchronous Drive – Optimized tooth design ensures smooth engagement between the belt and pulley, maintaining constant transmission ratio and preventing slippage.

High-Precision Manufacturing – CNC machining guarantees accurate tooth pitch, concentricity, and minimal circular runout according to international standards.Dynamic balancing eliminates eccentric vibration at high speed, while rigorous dimensional and surface inspections ensure consistent assembly.

Reliable Precision Drives – Engineered for precision positioning systems, these pulleys deliver high-precision, quiet operation, available in 2mm, 3mm, 5mm, and 8mm standard pitch specifications.

| Model. No. | Synchronous pulley for high precision positioning |

| Material | 6061/S45C |

| Module | 2GT/3GT/5GT/8YU |

| Shape | A/B/D/E/F/K |

| Transport Package | Each item should be packed in a polyethylene bag or wax paper and placed in one or more boxes. |

| Trademark | iHF |

| HS Code | 8448399000 |

| Manufacturing Process | Casting |

| Surface Treatment | Electroplating |

| Surface Color | Clear/Black/Silver |

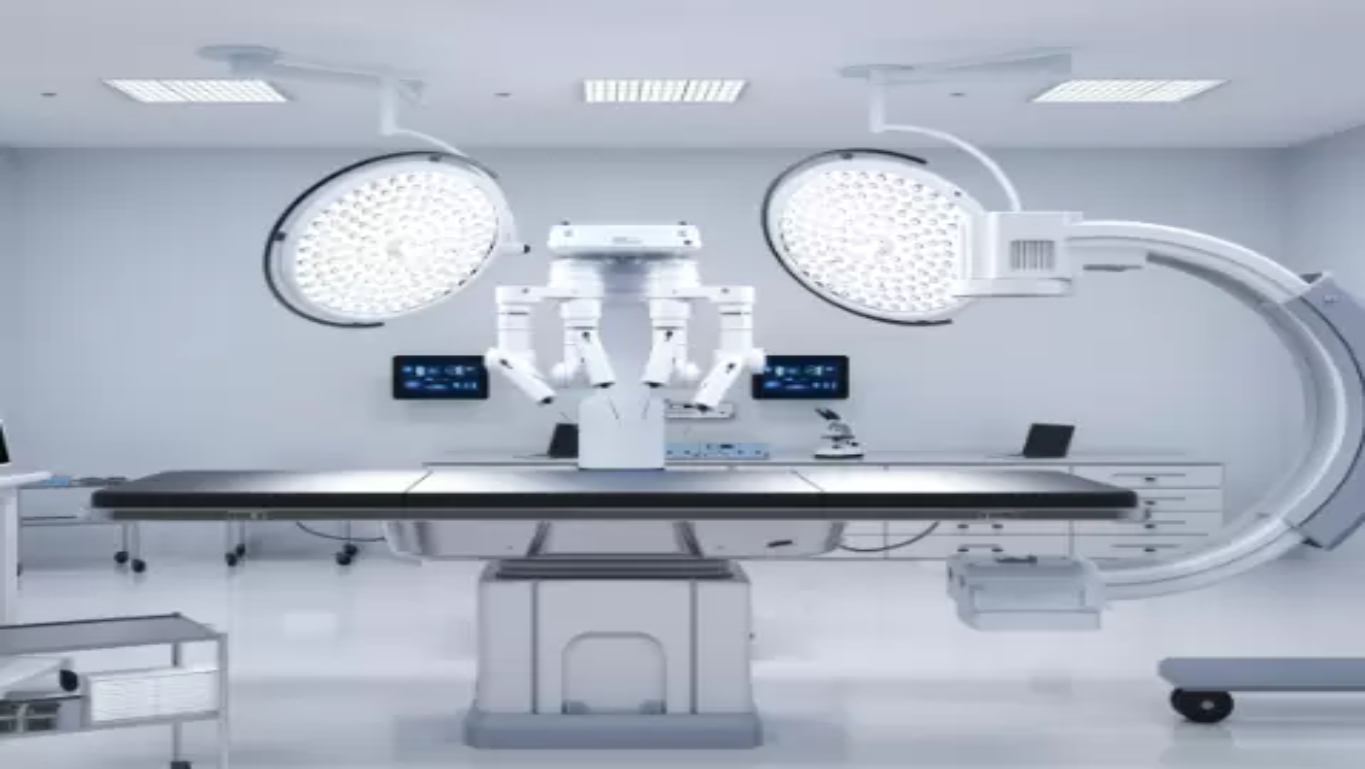

| Application | Medical industry/Robot industry/Automation industry |

| Specification | Standard |

| Origin | Dongguan(Mainland) |

| Production Capacity | 550000 PCS/Year |

| Product | Standard timing pulley 2GT/3GT/5GT/8YU |

| Customized | OEM, drawings or samples customized |

| Basic Shape | Type A/B/D/E/F/K |

| Surface Treatment | Clear anodizing, Black anodizing, Hard anodizing, Nickel plating, Black oxide |

| Material | 6061(aluminum);S45C(45# steel);SUS304(stainless steel) |

| Bore | Through hole, Tapped hole, Counterbore, Keyway |

| Tolerance Control | Outer diameter ±0.005mm Length diameter ±0.005mm |

| Standard | DIN, ISO/GB, AGMA, JIS |

| Teeth Accuracy | DIN, ISO/GB Class 4, AGMA Class 13, JIS Class 0 |

| Weight | Max 15 Tons |

| Testing Equipment | Projecting apparatus, salt spray test, durometer, and coating thickness tester, 2D projector |

| Producing Equipment | CNC machine, automatic lathe machine, stamping machine, CNC milling machine, rolling machine, lasering, tag grinding machine etc. |

| Machining Process | Gear hobbing, Gear milling, Gear shaping, Gear broaching, Gear shaving, Gear grinding and Gear lapping |

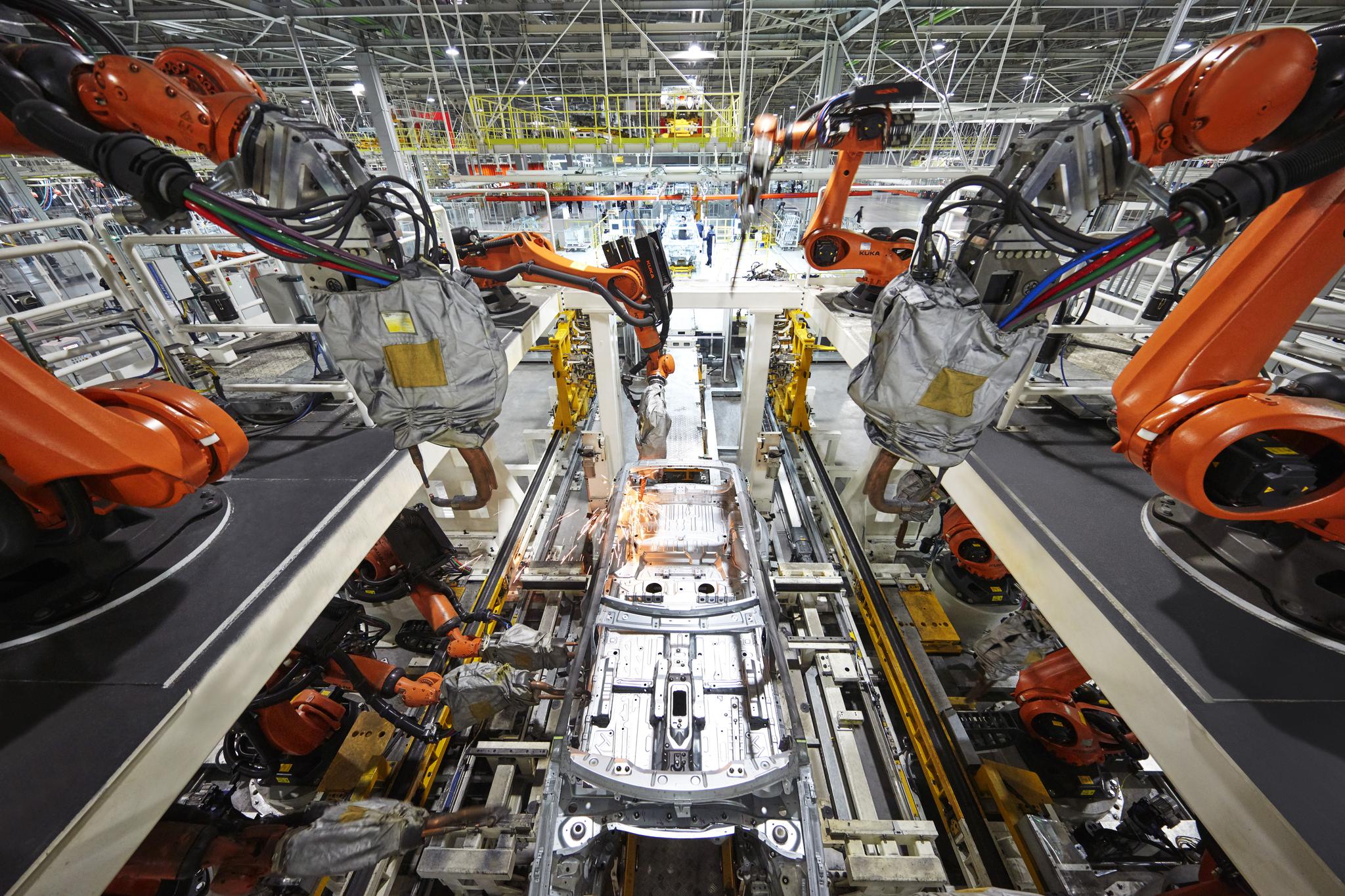

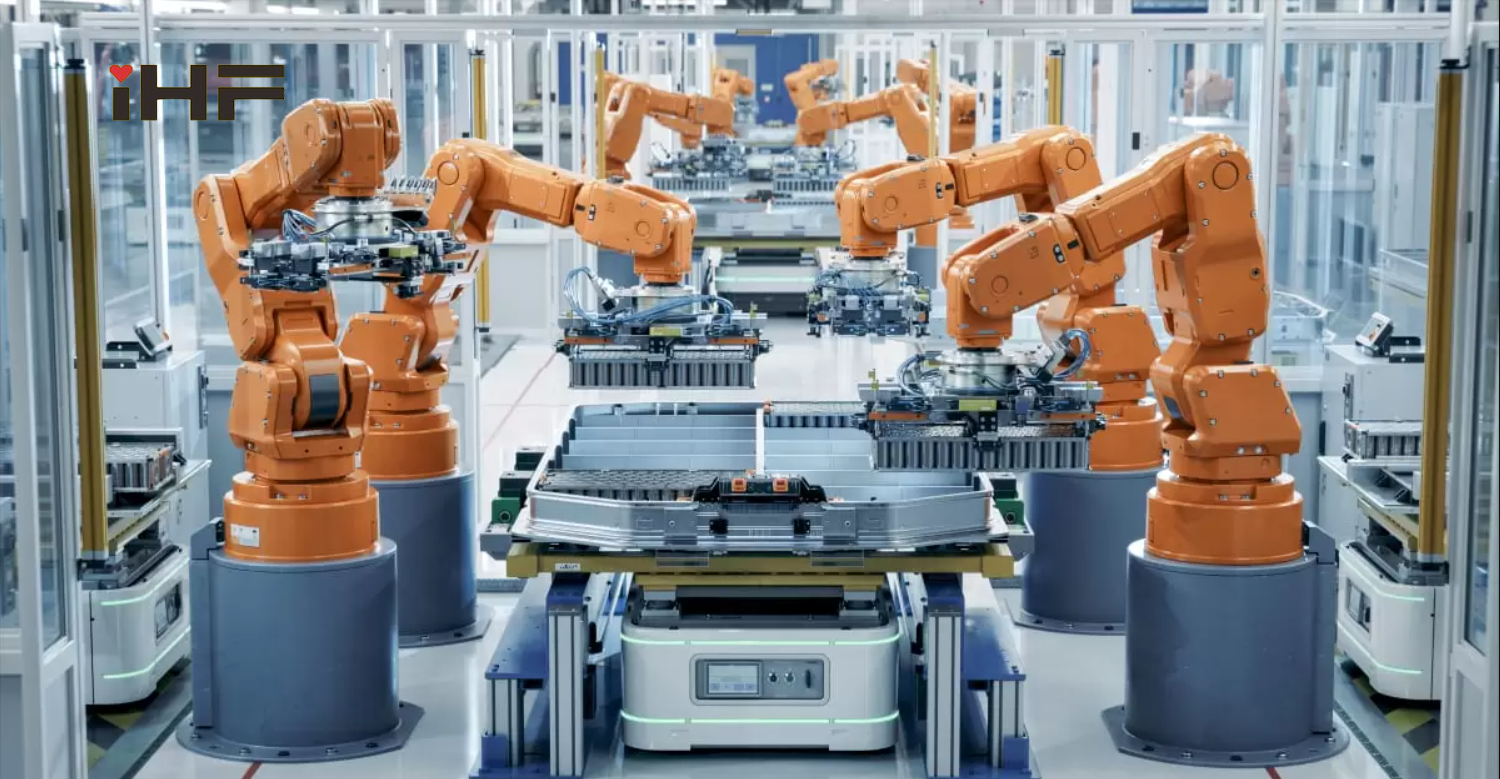

| Application Industry | Robot industry, Medical industry, Manufacturing machine industry, Automation industry, 3C industry equipment, Packaging industry, UAV industry, New energy industry |

-

*

-

*

-

*

-

-

EN

EN Request Quote

Request Quote