Learn more >

The Application of iHF Planetary Reducers in New Energy Lithium Battery Equipment

The new energy industry, particularly the lithium battery sector, has experienced significant growth in recent years due to the increasing demand for energy storage solutions in electric vehicles and renewable energy systems. Lithium battery production involves complex processes that require high precision, efficiency, and reliability. iHF planetary reducers have emerged as a key component in this industry, providing the necessary motion control and power transmission for various equipment used in lithium battery manufacturing. Two notable customer cases that demonstrate the effectiveness of iHF planetary reducers are Colibri and Yinghe Technology.

Colibri and Its Requirements

Colibri is a leading company in the field of new energy automation equipment, specializing in the research, development, production, and sales of lithium battery production machinery. The company's products cover a wide range of applications, including electrode manufacturing, cell assembly, and testing equipment. To maintain its competitive edge, Colibri requires its equipment to operate with high precision, stability, and efficiency. This is where iHF planetary reducers play a crucial role.

iHF planetary reducers are used in Colibri's equipment for their high transmission accuracy, which ensures precise positioning and movement of various components during the battery production process. For example, in electrode manufacturing machines, the reducers provide accurate control of the coating and drying processes, resulting in uniform and high-quality electrodes. In cell assembly equipment, the reducers ensure precise alignment and assembly of battery cells, minimizing errors and improving production efficiency.

Yinghe Technology and Its Requirements

Yinghe Technology is another prominent player in the new energy industry, known for its advanced lithium battery production equipment. The company offers a comprehensive range of solutions, including intelligent digital factory solutions for lithium battery manufacturing. Yinghe Technology's equipment requires reliable and efficient motion control to handle the high-speed and high-precision operations involved in battery production.

iHF planetary reducers are integrated into Yinghe Technology's equipment to meet these requirements. The reducers' high torque transmission capabilities enable them to handle the heavy loads and high forces encountered during battery production, such as in the pressing and forming processes. Additionally, the compact design of iHF planetary reducers allows for efficient integration into the equipment, saving space and optimizing the overall layout of the production line.

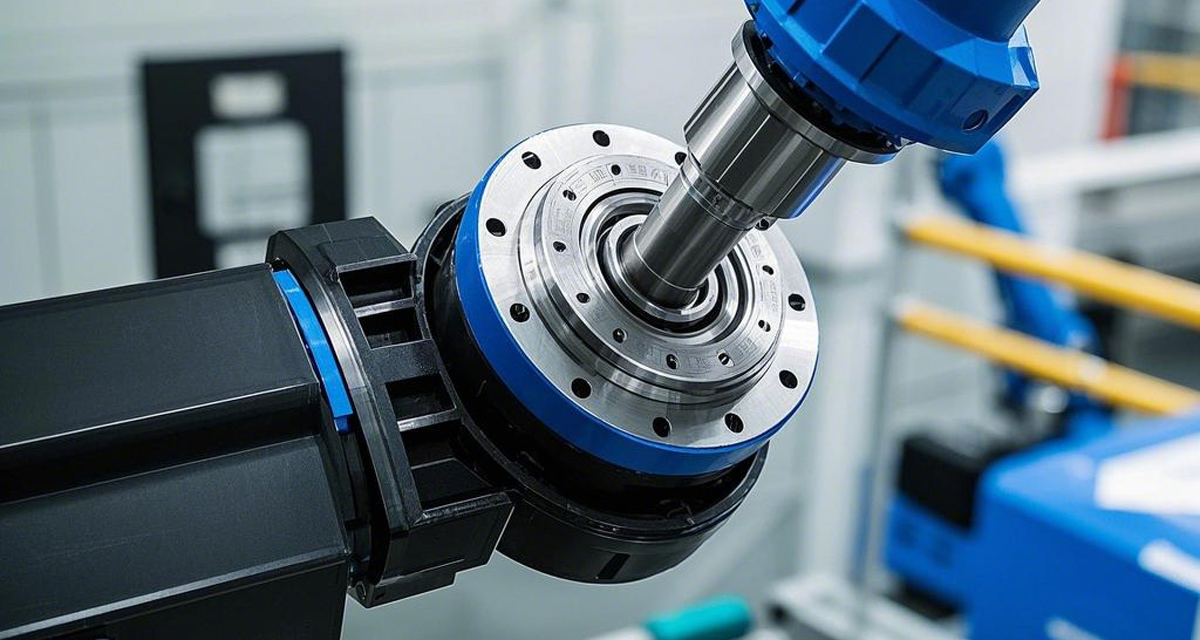

The Advantages of iHF Planetary Reducers

iHF planetary reducers offer several advantages that make them suitable for new energy lithium battery equipment:

High Precision

iHF planetary reducers have high transmission accuracy, which is essential for the precise positioning and movement of components in lithium battery production. This ensures consistent quality and performance of the batteries produced.

High Torque Transmission

Lithium battery production often involves high loads and forces, especially in processes such as pressing, forming, and assembly. iHF planetary reducers can handle these high torque requirements, providing reliable power transmission and ensuring smooth operation.

Compact Design

The compact size of iHF planetary reducers allows for efficient integration into various equipment, saving space and optimizing the layout of the production line. This is particularly important in the lithium battery industry, where space is often limited.

Durability and Reliability

iHF planetary reducers are known for their robust construction and high-quality materials, offering long-term durability and reliability with minimal maintenance requirements. This ensures continuous operation and reduces downtime, maximizing productivity.

The Application Cases at Colibri and Yinghe Technology

In Colibri's electrode manufacturing machines, iHF planetary reducers are used to control the movement of the coating and drying mechanisms, ensuring uniform application and drying of the electrode materials. This results in high-quality electrodes with consistent performance. In cell assembly equipment, the reducers precisely control the alignment and assembly of battery cells, minimizing errors and improving production efficiency.

At Yinghe Technology, iHF planetary reducers are used in various stages of battery production, including pressing, forming, and assembly. The reducers' high torque transmission capabilities enable the equipment to handle heavy loads and high forces, ensuring reliable operation and consistent quality. The compact design of the reducers also allows for efficient integration into the production line, optimizing space utilization and overall efficiency.

The application of iHF planetary reducers in new energy lithium battery equipment, as demonstrated by the cases of Colibri and Yinghe Technology, highlights the significant role these components play in enhancing the performance and efficiency of lithium battery production. Their high precision, high torque transmission, compact design, durability, and reliability make them an ideal choice for manufacturers in the new energy industry. As the demand for energy storage solutions continues to grow, iHF planetary reducers are expected to play an even more important role in the development of the lithium battery industry.

EN

EN Request Quote

Request Quote