Learn more >

The Application of iHF Planetary Reducers in Laser Cutting Machines

Laser cutting machines have become an indispensable part of modern manufacturing due to their high precision, speed, and versatility. Among the key components that contribute to the performance of these machines are planetary reducers, which play a crucial role in controlling the movement and accuracy of the laser cutting head. iHF planetary reducers have gained significant attention and application in this field, and one notable customer case is Han's Laser.

Han's Laser and Its Requirements

Han's Laser is a leading company in the laser equipment manufacturing industry, known for its high-quality laser cutting machines. To maintain its competitive edge, Han's Laser requires its equipment to have high precision, stability, and efficiency. In particular, the laser cutting head needs to be accurately positioned and smoothly controlled to achieve intricate cuts and high-quality finished products. This is where the iHF planetary reducer comes into play.

The Advantages of iHF Planetary Reducers

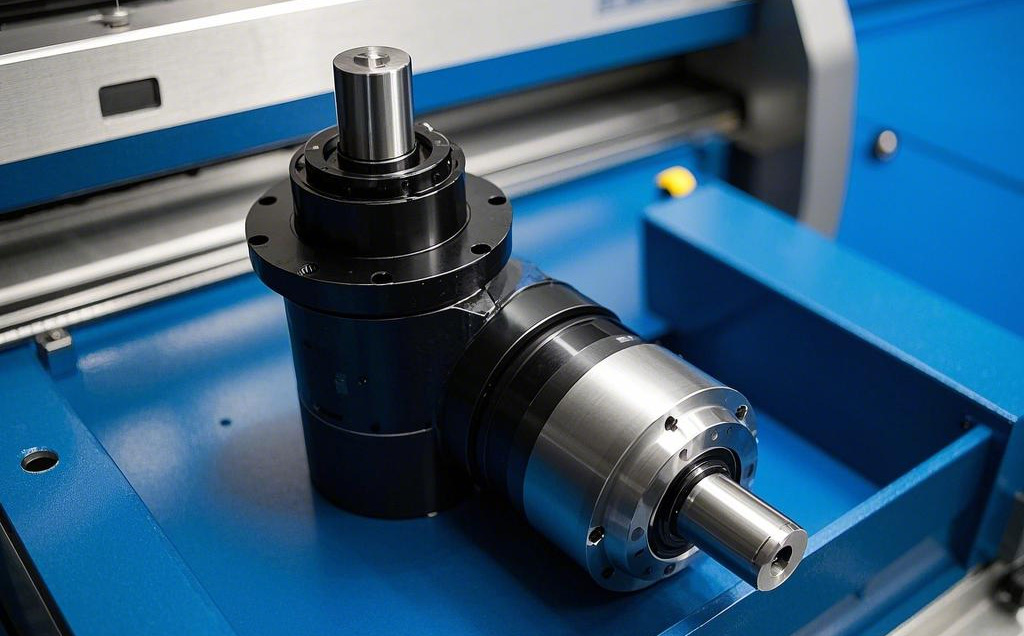

iHF planetary reducers offer several advantages that make them suitable for laser cutting machines:

High Precision

iHF planetary reducers have high transmission accuracy, which ensures the precise movement of the laser cutting head along the X, Y, and Z axes. This precision is crucial for achieving intricate cuts and complex shapes with tight tolerances, meeting the high standards of Han's Laser.

High Torque Transmission

Laser cutting machines often encounter high loads and forces during the cutting process, especially when cutting through thick or hard materials. iHF planetary reducers have high torque transmission capabilities, enabling them to withstand these forces and provide reliable motion control even under demanding conditions. This ensures consistent cutting performance and meets the requirements of Han's Laser for processing various materials.

Compact Design

The compact size of iHF planetary reducers allows for efficient integration into the laser cutting machine's overall design, minimizing space requirements and maximizing workspace utilization. This is particularly advantageous for Han's Laser, as it enables the design of more compact and efficient laser cutting machines.

Durability and Reliability

iHF planetary reducers are known for their robust construction and high-quality materials, offering long-term durability and reliability with minimal maintenance requirements. This ensures the continuous operation of the laser cutting machine, reducing downtime and maximizing productivity for Han's Laser.

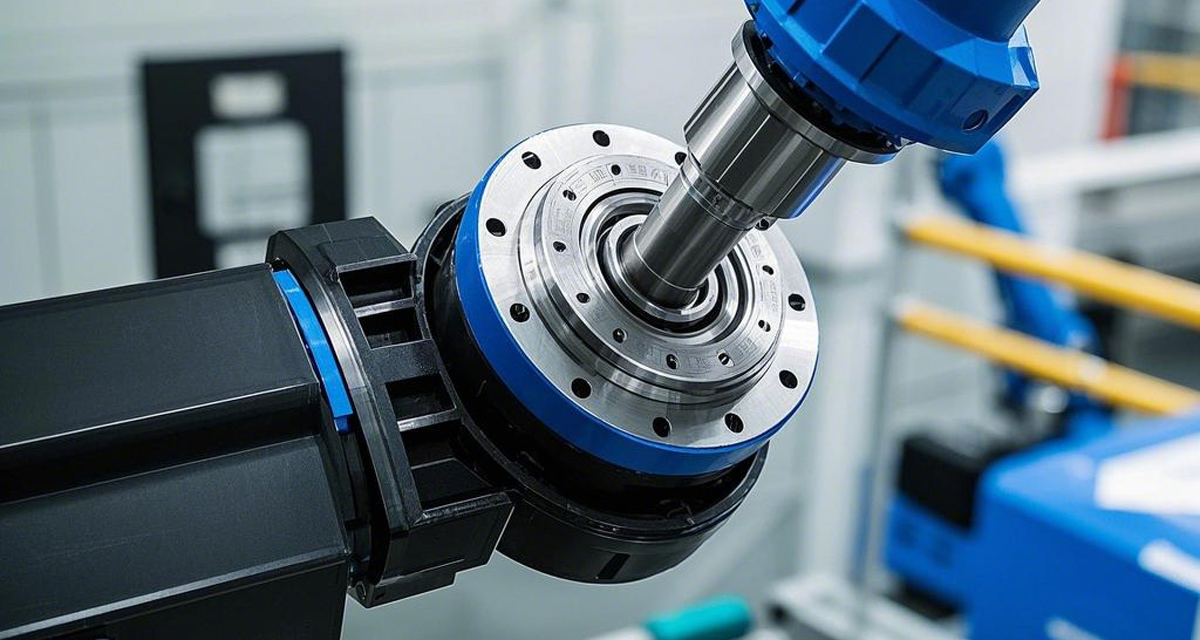

The Application Case at Han's Laser

In the laser cutting machines of Han's Laser, iHF planetary reducers are integrated into the motion control system responsible for positioning and guiding the laser cutting head. The reducers precisely control the movement of the cutting head, ensuring accurate positioning of the laser beam on the workpiece. This precision is crucial for achieving high-quality cuts and meeting the stringent requirements of Han's Laser's customers.

Moreover, the smooth motion control provided by iHF planetary reducers prevents vibrations and oscillations during the cutting process, resulting in cleaner cuts and higher quality finished products. The high torque transmission capabilities of the reducers also enable Han's Laser's machines to handle heavy loads and cut through thick materials with ease.

Conclusion

The application of iHF planetary reducers in laser cutting machines, as demonstrated by the case of Han's Laser, highlights the significant role these components play in enhancing the performance and efficiency of laser cutting equipment. Their high precision, high torque transmission, compact design, durability, and reliability make them an ideal choice for manufacturers like Han's Laser, who strive to provide high-quality and efficient laser cutting solutions to their customers. As technology continues to advance, iHF planetary reducers are expected to further enhance their capabilities and contribute to the ongoing evolution of laser cutting technology.

EN

EN Request Quote

Request Quote