Learn more >

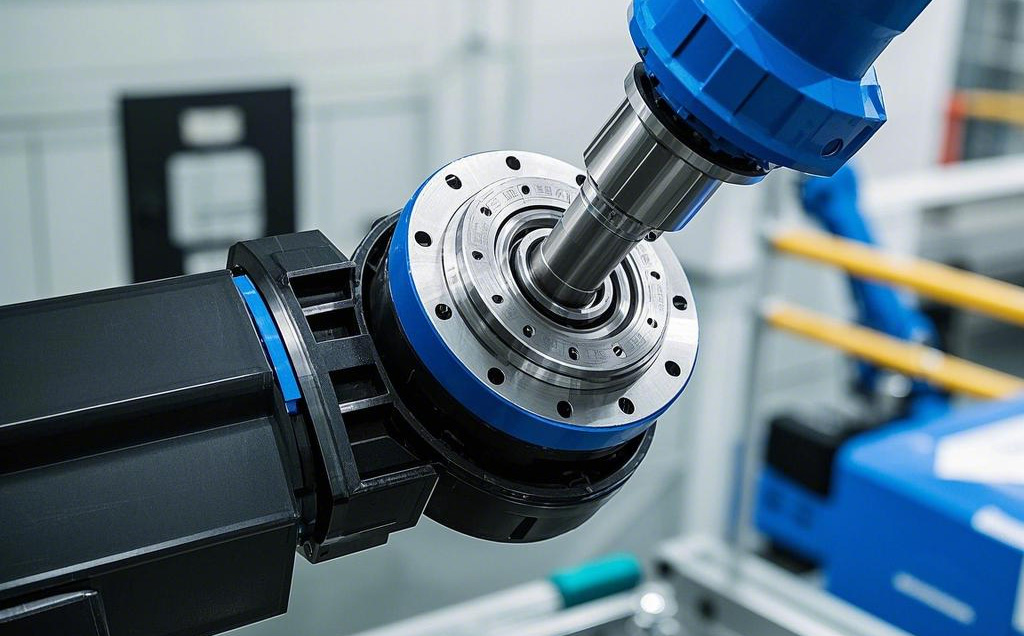

The Application of iHF Planetary Gear Reducers in Industrial Robots

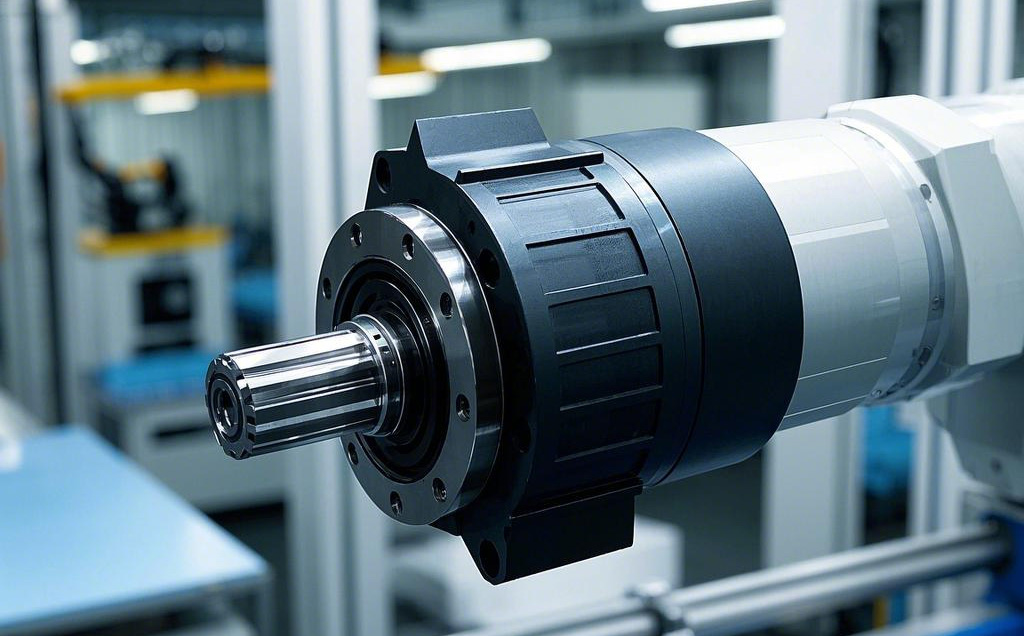

Industrial robots require precision, durability, and compact design, and iHF planetary gear reducers excel in meeting these demands. With high torque density, low backlash (<1 arcmin), and compact structures, iHF reducers optimize robotic performance in tasks ranging from assembly to heavy-duty handling.

Key Advantages

1. High Precision: iHF reducers achieve positioning accuracy of ±0.1 arcmin, critical for robotic welding and electronics assembly.

2. Compact Design: Their space-saving structure enables integration into robot joints, even in confined spaces.

3. High Load Capacity: Multi-gear engagement distributes stress, supporting heavy loads up to 10,000 N·m.

4. Customization: Tailored solutions for specific robotic applications, such as high-frequency motion or extreme environments.

Customer Case Studies

1. Kawasaki Robotics: Integrated iHF reducers into assembly-line robots, improving repeatability by 15% and reducing cycle time.

2. Topstar: Utilized iHF reducers in packaging robots, achieving 98% uptime and smoother motion control.

3. DEEP Robotics: Deployed iHF reducers in AI-driven robots, enhancing precision in complex tasks like object recognition and sorting.

4. UBTECH Robotics: Adopted iHF reducers for humanoid robots, ensuring seamless motion and high reliability in interactive applications.

5. Zowei Technology: Incorporated iHF reducers into SCARA robots, enabling micron-level precision in PCB manufacturing.

iHF planetary gear reducers have become a cornerstone in industrial robotics, driving advancements in automation through precision engineering and adaptive solutions. Partnerships with leaders like Kawasaki and UBTECH underscore their role in shaping the future of smart manufacturing.

EN

EN Request Quote

Request Quote